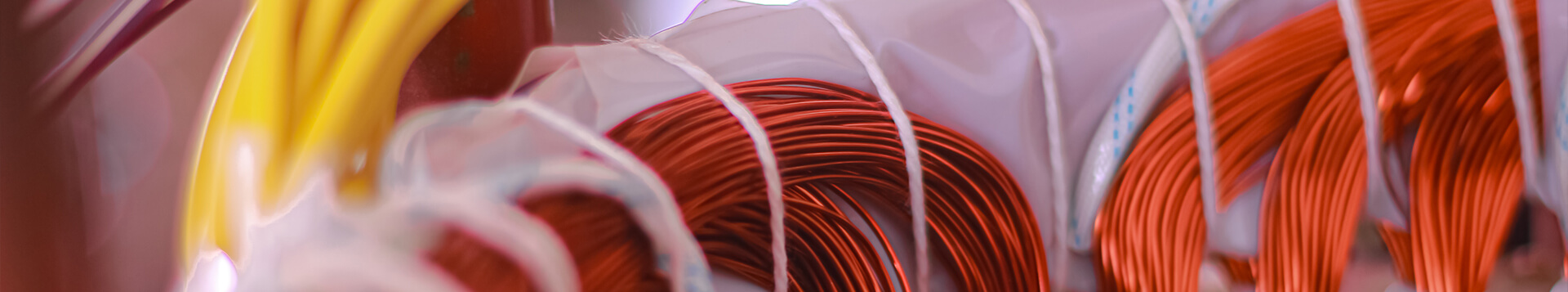

SynChem – Resins & Varnishes Synthite AC-41 Polyurethane varnish

Synthite AC-41 is an air drying finishing varnishes based on polyurethane.

Synthite AC-41 has the following excellent properties:

- fast drying - units can be handled in 30 min.

- easy application (dipping, brushing, spraying)

- hohe Temperaturbeständigkeit

- superior abrasion resistance

- excellent adhesion to most surfaces

- transformer oil resistance ASTM D 155-55

- corrosion and humidity resistance

Application

Electrical engineering and electronic devices.

Standards

Class H (180 °C) acc. UL 1446, MW 35-C, Twisted Pairs.

Delivery forms

4.5 kg, 22.5 kg and spray bottles on request.

Base

Clear

Color

Clear

Storage

Store in cool dry place (max. 30 °C) away from direct sunlight. Protect from moisture and humidity. Shelf life is 36 months when stored in closed original container at max. 30 °C.

Hardening

Curing is possible in explosion protected environments under a fume hood at ambient conditions:

Air drying times at 25 °C:

- 10 min. dust-dry

- 1 h touch-proof

- 48 h cured

Protection

Cured Synthite AC-41 is biologically inactive and safe to health. Always refer to the safety data sheet and implement common protective measures when processing the varnish.

Cleaning

Clean tools with thinner T 200 in time. Maintenance and care of coating equipment, especially cleaning, must be carried out according to operational requirements. Always refer to the user manual of the equipment.

Processing

When spray-coating with thinner T 200, Synthite AC-41 is adapted to processing viscosities in common manual spraying nozzles. Usually you 20-25 % thinner. It is possible to adjust the viscosity with T200 for dip coating. Before longer air contact, ensure that the dipping bath surface does not become dry by placing a nitrogen blanket. Synthite AC-41 is supplied ready-to-use for brushing application. Recommended coating thickness: less than 30-40 µm.

Always observe the specifications on the safety data sheet and relevant safety organisation regulations.

Technical data

| Property | Unit of measure | Conditions | Value | Test method |

|---|---|---|---|---|

| Coating thickness | µm | 60-75 | ASTM D-115 |

| Property | Unit of measure | Conditions | Value | Test method |

|---|---|---|---|---|

| Dielectric strength | kV/mm | dry / 0.025 mm film thickness | 80 | |

| Dielectric strength | kV | after 24 h water immersion / 0.025 film thickness | 48 | ASTM D-115 |

| Property | Conditions | Blistering | Rusting | Cracking | Test method |

|---|---|---|---|---|---|

| Resistance | Water | no | no | no | ISO 4628/2-3-4 |

| Resistance | 1% Natrium hydroxide | no | no | no | ISO 4628/2-3-4 |

| Resistance | saltwater | no | no | no | ISO 4628/2-3-4 |

| Resistance | 10 % sulfuric acid | no | no | no | |

| Resistance | no |

| Property | Unit of measure | Conditions | Values | Test method |

|---|---|---|---|---|

| Dilution | 4:1 | |||

| Specific density | g/l | 25 °C | 900±20 | |

| Viscosity | s | 25 °C | 50-65 | Ford Cup 4 |

| Viscosity | s | 25 °C | 40-60 | ISO Cup 6 |