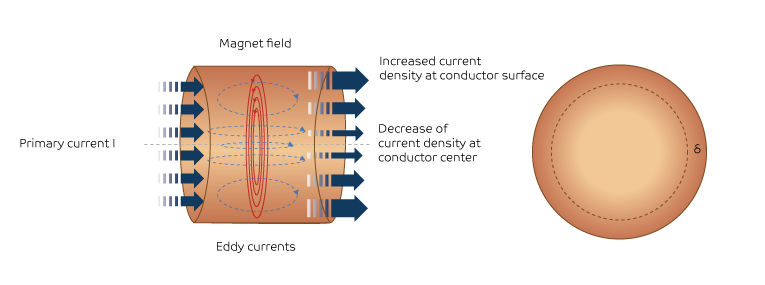

| Frequency f | Skin depth (copper) |

| 10 kHz | 0.66 mm |

| 50 kHz | 0.29 mm |

| 100 kHz | 0.21 mm |

| 500 kHz | 93 μm |

| 1 MHz | 66 μm |

| 5 MHz | 29 μm |

| 50 Mhz | 9.3 μm |

HF litz wires – flexible and robust conductors for the high frequency range

HF litz wires (high-frequency stranded conductors) are used wherever special flexibility and good properties are required with regard to high-frequency applications. By individually adapting the parameters, such as number and thickness of the individual wires, flexibility or insulation, we design the optimum conductors for your application.

We offer both stranded wires and high-frequency litz wires. The fundamental difference between HF litz wires and stranded wires is the insulation of the individual wires. The main component of HF litz wires are the individual enamelled wires which are available in various combinations of conductor material and insulation varnish.

You have questions according to our HF litz wires want to send an inquiry?

Our sales representative will be happy to help you.

Our strands and high-frequency litz wires at a glance

We offer you a large selection of stranded wires which we manufacture according to your requirements. Select one of our litz wire types and plan your individual product together with our product manager.

Basic litz wires

Basis for our litz wires is round bare wire. For our high-frequency litz wires we use our varnish-insulated wires V155, V180 and W210.

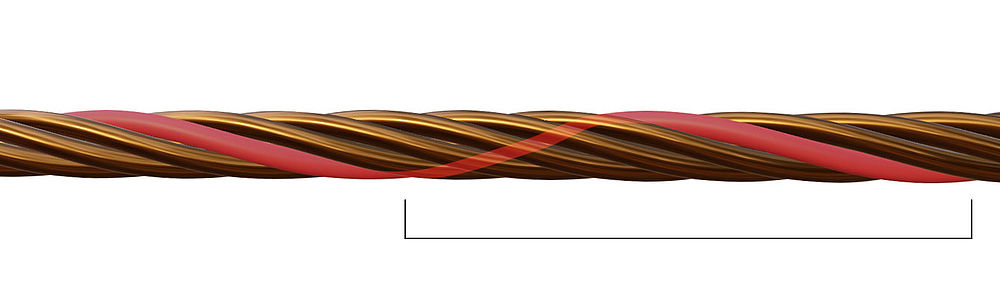

Pressed or profiled stranded wires

To increase the filling factor of the conductor material and thus increase efficiency, it is also possible to profile HF litz wires. For this purpose, we shape a correspondingly pre-constructed round strand into a rectangular form. Since the litz wire is exposed to mechanical load during this process, we ensure a balanced ratio of height x width. Do you need advice on stranded or profiled litz wires? We will be happy to answer your questions.

Wrapped or braided HF litz wires

Determine the properties such as breakdown voltage, thermal resistance or flexibility by means of best suitable insulating materials. Take advantage of our know-how in the production of flexible insulating materials and adhesive tapes. We select the perfect material together with you from our range of SynTherm® insulating materials and adhesive tapes and will be happy to advise you on the material combination, type of wrapping and degree of overlap of the individual insulation tapes.

Have the HF litz wire covered with very fine material such as natural silk, polyester or nylon, thereby increasing its stability and impregnation capacity.

Individual composition of HF litz wires for your application

Basically, HF litz wires consist of several (hundred) individual, thin stranded enamelled wires. They create an electrical conductor which, due to its special construction, reduces eddy current losses caused by the skin and proximity effect. Typically, HF litz wires are used in frequency ranges from 10 kHz to 5 MHz.

Length of twist

The length of twist describes the distance that a single wire in the strand requires for a complete twist (360°). The following applies: the shorter the length of twist, the more compact, stiffer and dimensionally stable the strand.

Twist or lay direction

The twist or lay direction indicates the direction in which the wires of the strand are twisted or stranded. We distinguish between the S lay and Z lay. It is also possible to change the lay direction. This increases the mechanical stability, but at the same time reduces the flexibility of the strand.

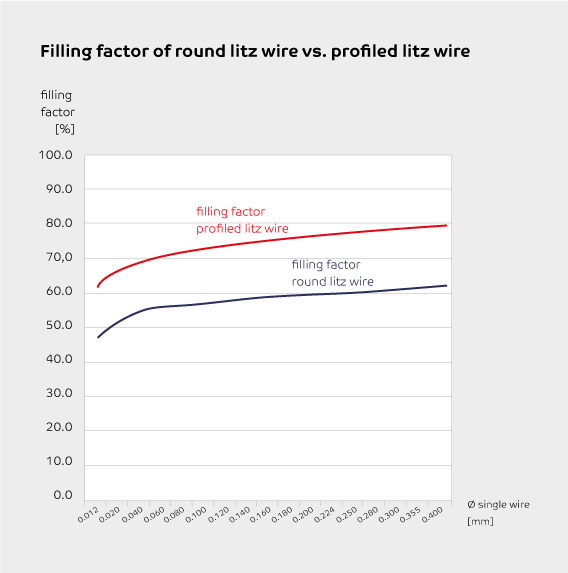

Filling factor

The fill factor describes the ratio of the effective cross-sectional area of the copper conductors to the theoretical maximum total cross-sectional area of the stranded wire. In the design of your HF litz wire, we strive to achieve the highest possible fill factor and thus optimize the performance of strands. Please take into account that the diameters of individual wires as well as the type of insulation, e.g. wrapped with aramid paper, have a decisive influence on the fill factor. Therefore, contact our technicians and design your individual HF litz wire together with us.

Types of litz wires

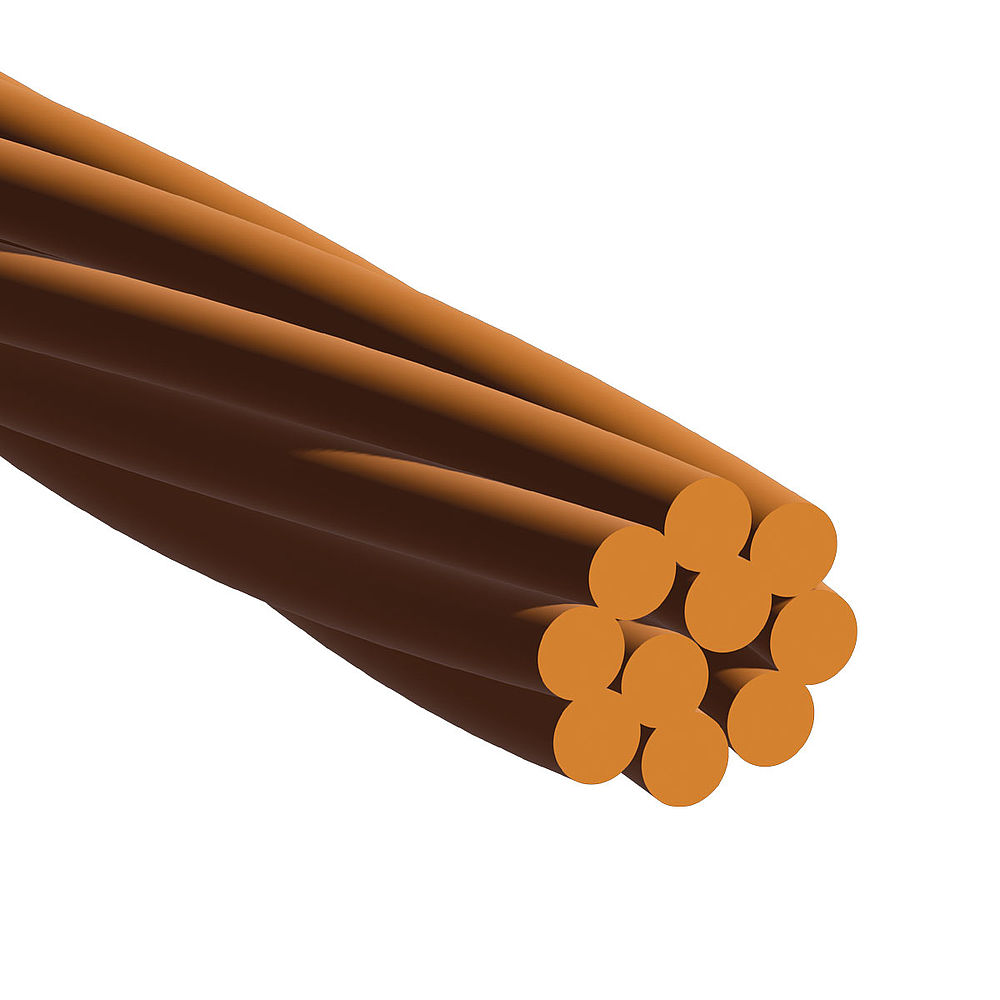

Depending on the thickness and number of individual wires, direct stranding is possible. In this case, the individual wires are bundled in such a way that the wires can move freely and take any position within the strand cross-section.

This strand construction is characterized by a centrally fixed stranded conductor around which the individual wires or strand bundles are arranged concentrically.

If you have certain power requirements or if the number of individual strands exceeds a limit, the litz wires are stranded in several steps. The exact structure of the bundle depends on the desired electrical and mechanical properties of the HF litz wire. We develop this structure according to your specifications.

To optimize the copper fill factor, we recommend using stranded wires with a rectangular profile, especially for chokes, transformers and disc coils. The starting product is always a round strand. This allows us to make better use of the winding space, but the flexibility decreases.

Do you have technical questions according to our HF litz wires? Contact our product manager who will be happy to help you.

In the following you will find information on the skin effect and the proximity effect. Two effects that occur in HF litz wires that lead to current displacement or loss.

Skin effect

The skin effect describes the current displacement effect in electrical conductors that are used with high frequencies in alternating current. The current density is higher on the surface of the conductor than inside.

This effect also occurs in single conductors.

The solution to the skin effect is to increase the surface area and use many thin individual wires - a stranded wire.

The following table shows the skin depth depending on frequency.

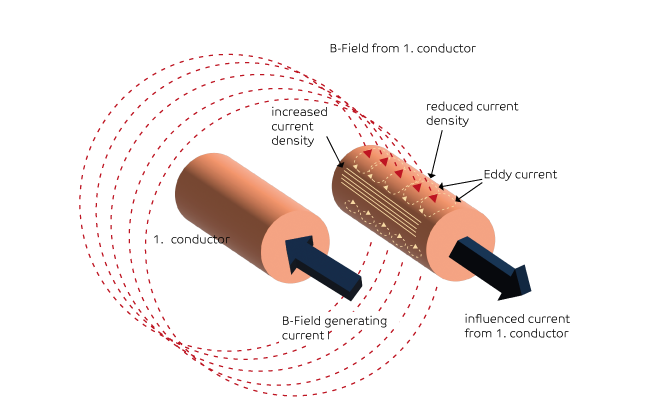

Proximity-effect

The proximity effect only occurs in conductor bundles and refers to the current displacement between two closely neighbouring conductors under the influence of alternating currents, due to eddy currents.

The alternating magnetic fields outside the copper conductor influence the neighbouring conductor, cause further conduction losses and generate heat. Varnish-insulated single wires and stranding of the single wires are the solution.

Single wire diameter against frequency range

The performance of HF litz wires depends on many of your design parameters. Thus, you can obtain similar performance results by varying different factors. We will work with you to develop a balanced design for your litz wire that meets your requirements and results in optimal performance.

The basis for designing stranded wires is the selection of suitable diameters for the corresponding individual wires. Due to the skin and proximity effect, there is a correlation to the frequency range of your application.

We have compiled the correlation between single wire diameter and frequency range for you in the following table.

| Frequency range kHz | Diameter single wire | ||

|

from |

to |

from |

to |

|

0.06 |

1 |

0.4 |

0.254 |

|

1 |

10 |

0.254 |

0.2 |

|

10 |

20 |

0.2 |

0.127 |

|

20 |

50 |

0.127 |

0.102 |

|

50 |

100 |

0.102 |

0.079 |

|

100 |

200 |

0.079 |

0.063 |

|

200 |

350 |

0.063 |

0.05 |

|

350 |

850 |

0.05 |

0.04 |

|

850 |

1400 |

0.04 |

0.03 |

|

1400 |

3000 |

0.03 |

0.02 |