电工胶带 - 为您量身定制的高技术含量产品

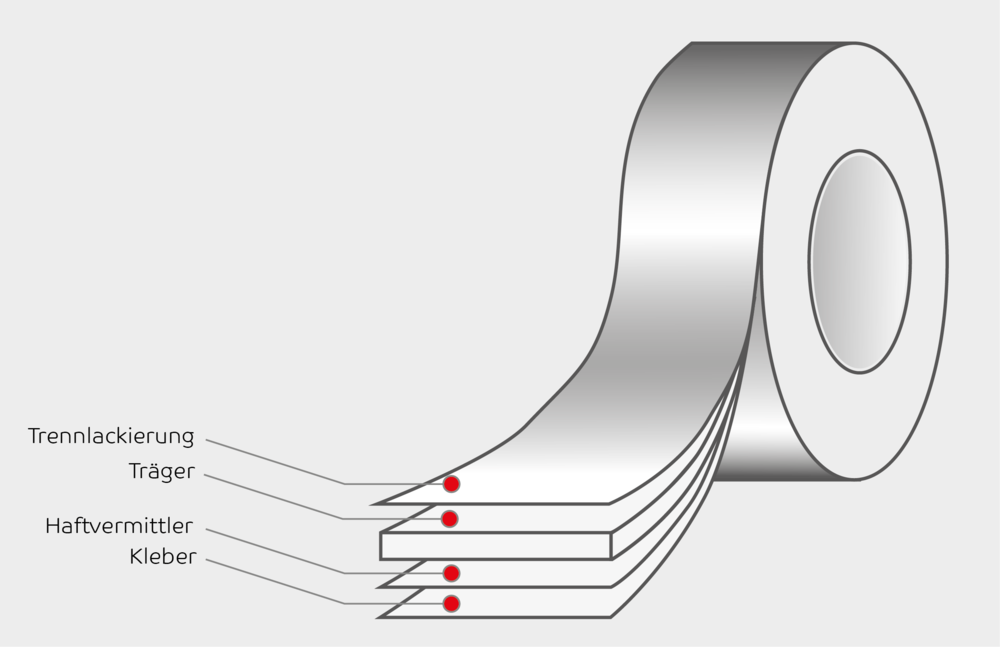

胶带总是由几层组成。底层材料也称为载体,通常是一种平面绝缘材料 ,是实际电气胶带的基础。

基材外面有一层脱模涂层。这层涂层具有憎粘性,可防止胶带自身粘连,并使胶带更容易松开。

背衬材料的内部涂有粘合剂,可确保背衬和粘合剂之间的永久粘合。然后将实际粘合剂涂在粘合剂上。

根据不同的应用,您可能需要不同结构的电工胶带。我们可为您提供多种不同的基材和粘合剂类型。不同基材的特性与相应的粘合剂相结合,形成了一种全新的、高技术含量的产品,可广泛应用于电气行业。

使用中的定制电气胶带

丝网印刷

在丝网印刷中,我们的 SynTape® B/ P.355和Isotape® 51350 PV3-2胶带尤其用于在印刷过程中覆盖大面积的未使用区域,从而防止油墨渗入。您可以使用我们的SynTape® PM.099 实现干净的分隔边缘。

最高质量的电工胶带 - 可申请 UL 认证

我们在内部的SynLab® 实验室进行了许多分析和测试,以确保最高质量。例如,我们的许多电工胶带都通过了 UL 认证。

如果您需要进一步测试,请联系我们的 SynLab® 专家。除材料分析和使用寿命测量外,我们还为您提供一系列测试和测量方法,以确保材料的质量。我们还为您提供新的认证、扩展或调整现有 UL 系统方面的支持。

产品系列

SynTape®, Intertape®, Isotape®SynTape® – Electrical Adhesive Tapes SynTape® B/ PT.45

SynTape® B/ PT.45 is a polyester/ polyester non-woven laminated adhesive tape with very good cushioning effect and a thermosetting rubber adhesive.

These tapes are characterised by their good ductility and resistance to tears.

Application

Particularly suitable as final insulation or phase insulation for difficult surfaces, for masking soldering points and the winding start and end. Partly UL approved.

Delivery forms

- Width: From 2.5 mm, in 0.1 mm increments

- Standard length: 50 m

- Core diameter: 76 mm (3“)

- Special widths on request

Glue

Rubber

Adhesive

one-sided

Storage

6 months at room temperature. Adhesive tapes should be stored in a cool, dry place at approx. 20 °C and 50 - 60 % relative humidity. The storage period should not exceed 6 months.

Punched parts, bent & formed parts

We offer a wide range of punched and formed parts: Rolls, individual parts unsorted, sorted or stacked, adhesive on one or both sides, non-adhesive, with or without a grip tab.

More about punched parts

Technical data

| Property | Unit of measure | |

|---|---|---|

| Type/ Ordering information | B/ PT.45 | |

| Standard colours | white | |

| Backing (Laminate) | Polyester / Polyester non-woven | |

| Backing thickness | mm | 0.180 |

| Adhesive | Rubber | |

| Thermal class | 130 °C/ B | |

| Electrolyt. corrosion value | 1 | |

| Dielectic strength | kV | 5 |

| Adhesiveness / Adhesion to steel | N/cm | 6.5 |

| Elongation at break | % | 20 |

| Tensile strength | N/cm | 45 |

| Total thickness | mm | 0.235 |