Wie können wir Ihnen behilflich sein?

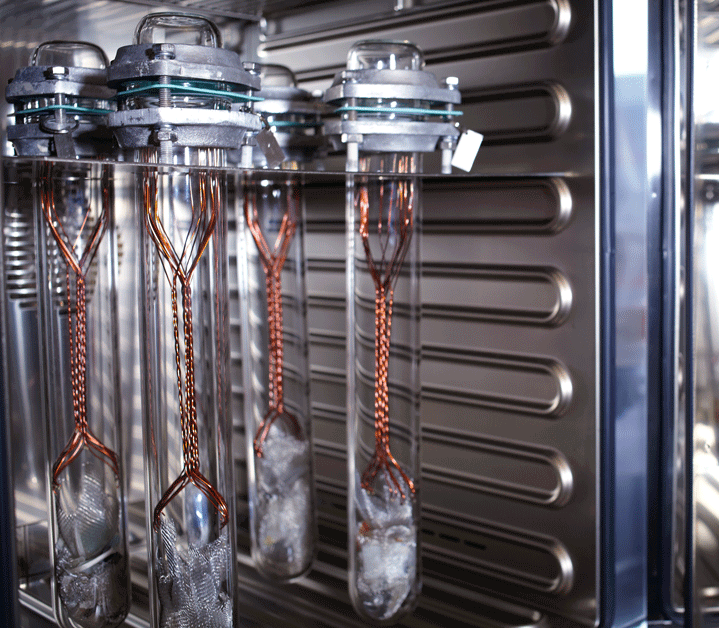

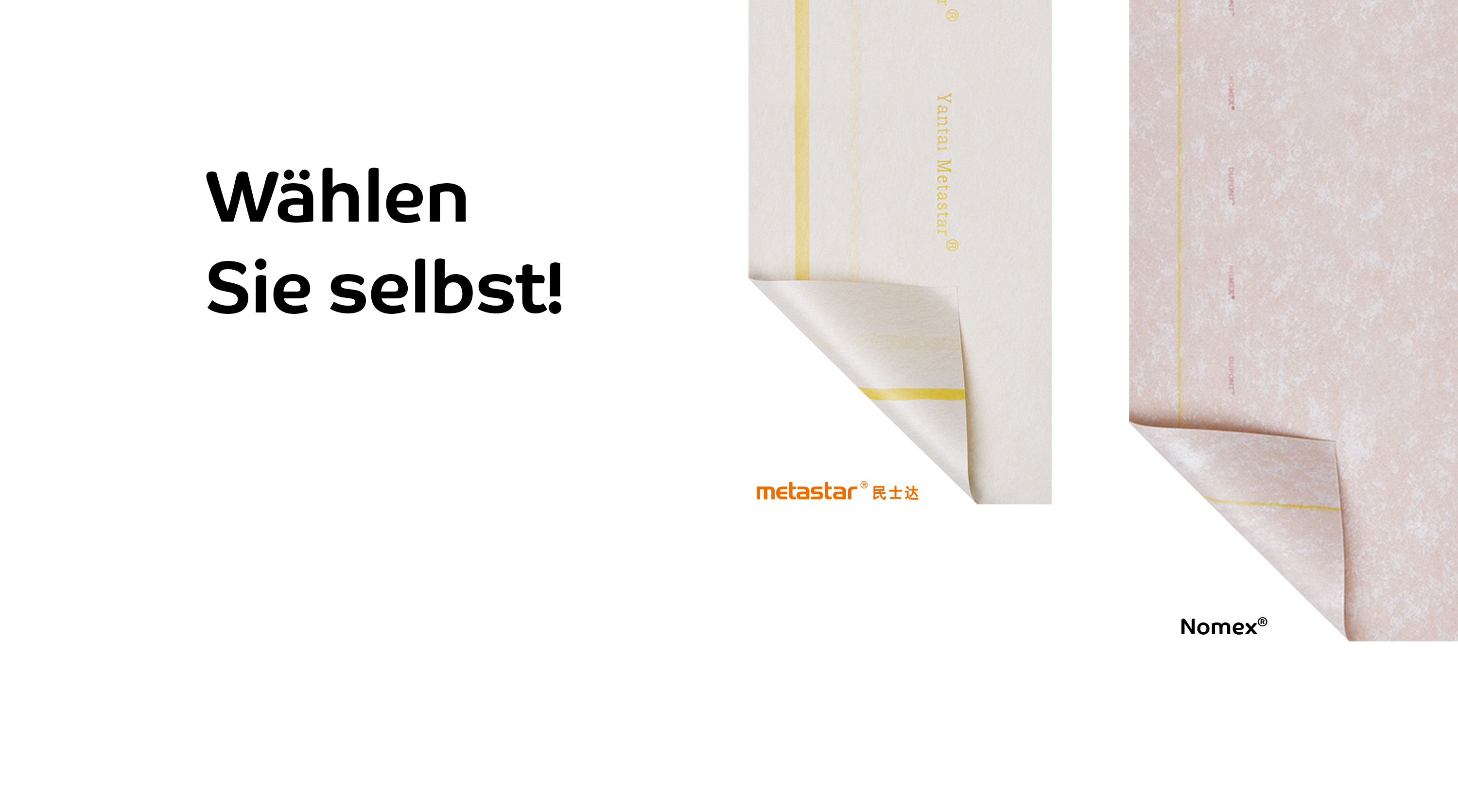

Die Kernkompetenz von SynFlex liegt in der Entwicklung, Herstellung und im Vertrieb von leitenden sowie isolierenden Produkten für Elektroisoliersysteme von Elektromotoren, Transformatoren und Generatoren.

+49 5235-968-0 info(at)synflex.de