SynChem – Resins & Varnishes WEVOPUR 403 FL PU encapsulating system

Two-component encapsulating system based on polyurethane.

After curing the resin has an excellent flexibility at low temperatures and thermal endurance. WEVOPUR 403 FL ist used with hardener WEVONAT 300 RE. Temperature range of use: -50 °C to +165 °C .

Application

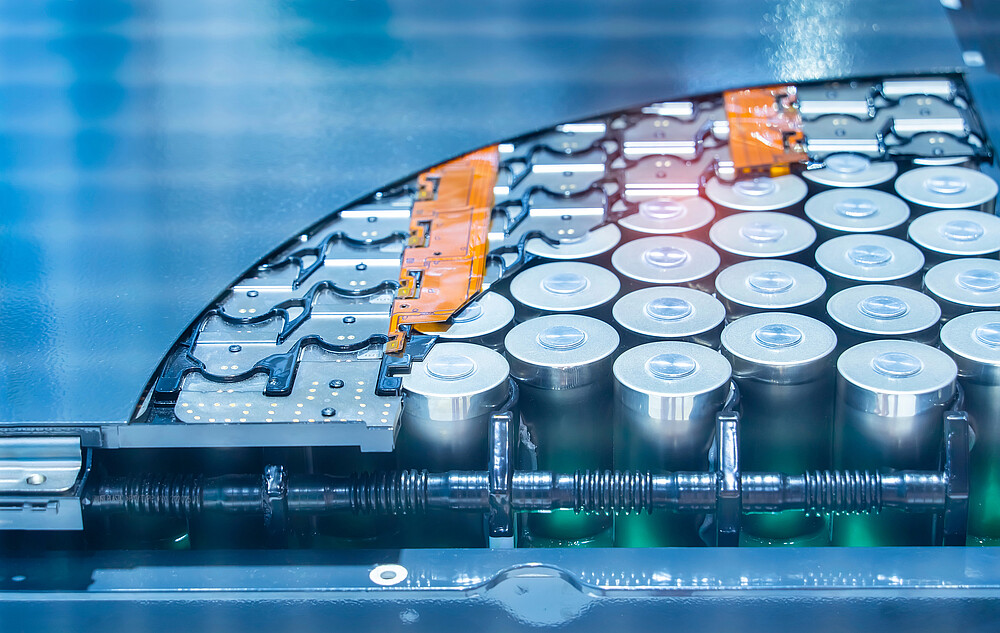

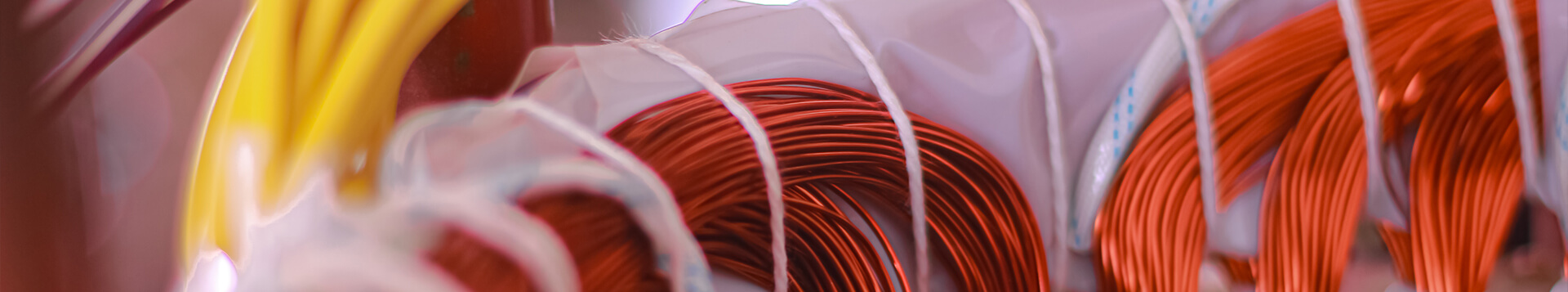

Encapsulation of applications that require high thermal resistance and endurance, like coils, sensors or PCBs. Especially for automotive or ex-proof applications.

Standards

- Class F

- RTI 155 °C

- UL 94 V 0 (1.5 mm)

- UL File E 108835

Delivery forms

30 kg metal container and 250 kg barrel.

Color

WEVOPUR 403 FL: black (standard)

WEVONAT 300 RE: brown

Storage

6 months after production in closed original containers wiht dry storage between 15 and 25 °C.

- Store resin (A component, polyol) and hardener (B component, Isocyanat) dry and at temperatures between 15 °C and 25 °C. Store on pallets or collecting tray and do not expose to draft.

- At temperatures below 15 °C the hardener can crystallise which can be seen by opacity and/or clumps/crystals (usually hardeners are clear, transparent liquids in spite of their dark brown colour). In this case the hardener should not be used anymore.

- At temperatures higher then 25 °C the sedimentation of fillers contained in the resin component is accelerated. As a consequence it is more difficult to prepare (stir) the resin.

Hardening

Pot life: 30 - 50 min at room temperature, depending on coat thickness and pouring volume.

Curing time: 12 - 24 h at room temperature

Complete chemical curing: 10 - 14 days at room temperature

- High air moisture may lead to forming of bubbles. Reference value: the rel. air humidity should not exceed 40 - 60 %, depending on the product.To avoid a reaction of the surface curing should be in an air conditioned room, a container with low air moisture or in an oven.

- Elevated temperatures accelerate the curing.

- Curing temperature should not exceed 80 °C to avoid tensions of the resin.

- Final hardness of WEVOPUR 403 FL will be attained after 7 – 14 days at room temperature.

- This process can be accelerated by post curing at 60 - 80 °C for 16 - 24 h. This is relevant for potted components subjec to qualification tests.

- Electrical tests can usually be carried out straight after potting.

Protection

Safety data sheets and the data sheet M044 of the German Chemical Industry Association (BG Chemie) when using the liquid resin.

Cleaning

Since the cured resin is practically insoluble, tools and equipment have to be cleaned in sufficient time.

Processing

Our processing instructions please find here.

You have questions according to our resins and varnishes or want to send an inquiry?

Our product manager will be happy to help you.

Technical data

| Property | Unit of measure | Conditions | Value | Test method |

|---|---|---|---|---|

| Shore-D-hardness | 3 sec | 40 - 50 | acc. ISO 7619-1 | |

| Tensile strength | N/mm² | 9 | ISO 527-2 | |

| Elongation at break | % | 40 | ISO 527-2 | |

| E module | N/mm² | 110 | ISO 527-2 | |

| Water absorption | % | 0.6 | after 30 days storage in water | |

| Burning behaviour | 1.5 mm | V-0 | UL 94 |

| Property | Unit of measure | Condition | Value | Test method |

|---|---|---|---|---|

| Thermal conductivity | W/m*K | 0.73 | DIN EN ISO 22007-2:2015-12 | |

| Glass transition temperature | °C | -6 | TMA ISO 11359-2:2021-11 | |

| Coefficient of expansion | ppm/K | <-10 °C | 42 | TMA ISO 11359-2:2021-11 |

| Coeficient of expansion | ppm/K | >5 °C | 146 | TMA ISO 11359-2:2021-11 |

| Thermal class | F | IEC 60085 |

| Property | Unit of measure | Value | Test method |

|---|---|---|---|

| Dielectric strength | kV/mm | 30 | DIN EN 60243 |

| Specific volume resistance | Ω*cm | 10^14 | DIN EN 62631-3-1:2016 |

| Surface resistivity at 23°C and 50 % r.h. | Ω | 10^15 | DIN EN 62631-3-2:2016 |

| Dielectric constant ε at 50 Hz, 23 °C | 5.7 | DIN EN 60250 | |

| Dielectric constant; at 1 kHz, 23 °C | 5.3 | DIN EN 60250 | |

| Dielectric constant ε at 1 MHz, 23 °C | 4.7 | DIN EN 60250 | |

| Dielectric loss factor tan б at 50 Hz, 23 °C | 0.04 | DIN EN 60250 | |

| Dielectric loss factor tan б at 1 kHz, 23 °C | 0.04 | DIN EN 60250 | |

| Dielectric loss factor tan б at 1 MHz, 23 °C | 0.03 | DIN EN 60250 |

| Property | Unit of measure | WEVOPUR 403 FL | WEVONAT 300 RE | Resin/hardener-mixture |

|---|---|---|---|---|

| Mixing ratio | weight-% | 100 | 14 weight-% | |

| Viscosity (22 °C) | mPas | 12.000-18.000 | 10-40 | 2,000-3,000 |

| Density (22 °C) | g/cm³ | 1.62-1.68 | 1.20-1.24 |