SynChem – Resins & Varnishes WEVOSIL 20201/60 Gel

Solvent-free, additive crosslinking addition-curing two-component silicone-based casting resin system

The resulting gel-like molding material is characterized by good low-temperature flexibility and excellent behavior in the temperature shock test. Recommended temperature range: -60 °C to +200 °C.

The resin is processed together with WEVOSIL 20201/60 B.

Application

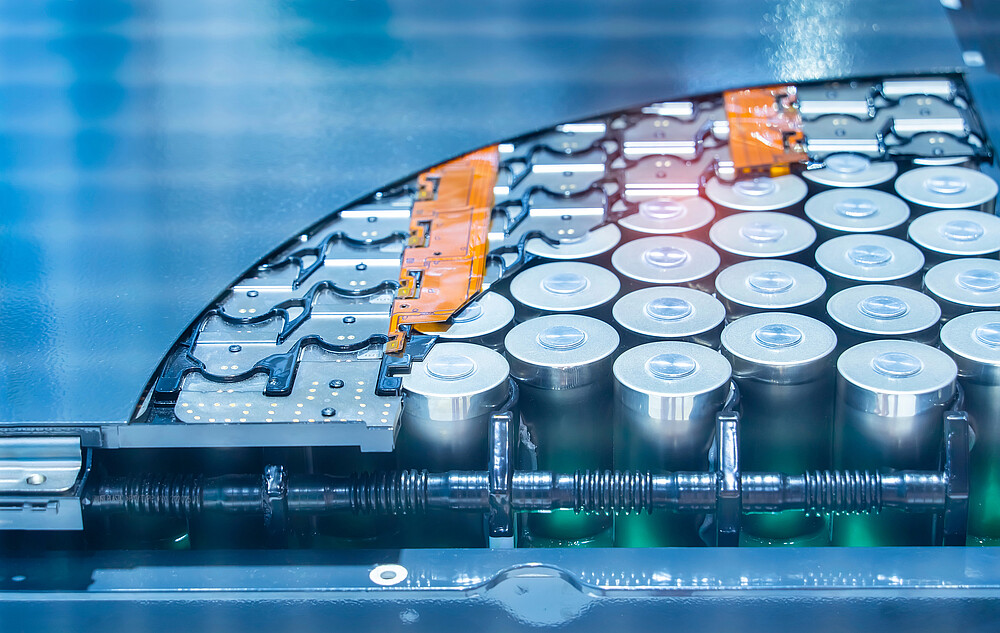

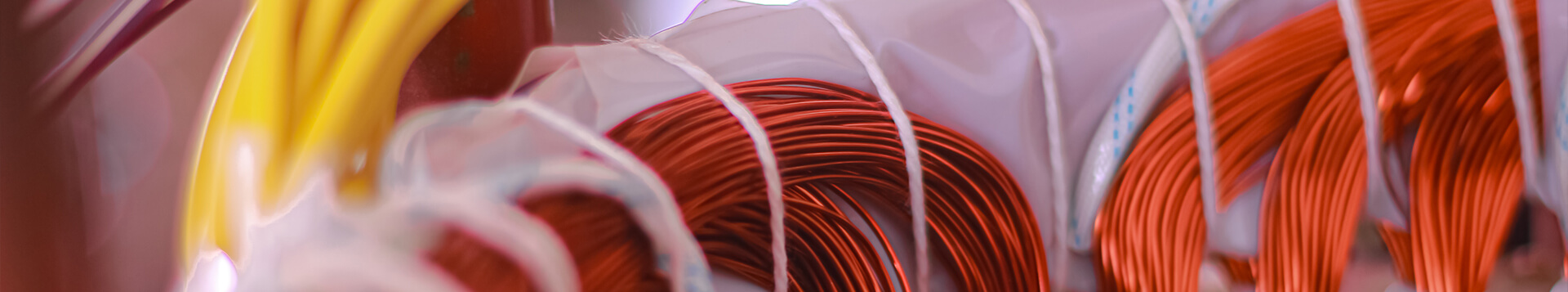

- Pressure-sensitive electrical components

- complete assemblies in SMD technology

Standards

- Temperature application range -60 °C - +200 °C

- Isolation class H

- RTI 180 °C

Delivery forms

10 kg and 25 kg containers and 200 L barrel

Color

WEVOSIL 20201/60 A: Natural

WEVOSIL 20201/60 B: Natural

Storage

Polymer (A-component) and crosslinker (B-component) must be stored dry and at a temperature of 5 °C to 30 °C and not in the open air. The containers should be stored upright and not

directly on the cold floor (floor temperature not below 5 °C). WEVOSIL 20201/60 Gel has a shelf life of 6 months after production.

At temperatures above 25 °C, the settling of the fillers contained in the casting compound is accelerated. The potting compound is then more difficult to homogenize.

Hardening

- Pot life: 50-60 minutes at room temperature, depending on layer thickness and casting volume.

- Curing time: 8 hours at room temperature, 1 hour at 100 °C

- Final chemical curing: several days at room temperature

Curing notes:

- Excessive humidity has a damaging effect on the uncured compound. If necessary, curing should take place in an air-conditioned room, a container with low humidity or in an oven.

- Curing at an elevated temperature (50 - 100 °C) accelerates the curing reaction and can influence the adhesion of the potting compound to the walls of the component.

- The WEVOSIL 20201/60 casting compound reaches its final hardness after a few days at room temperature..

- After approx. 8 hours curing at room temperature (or 1 h @ 100 °C) approx. 90 - 95 % of the curing takes place. To achieve the final hardness, post-curing can then be carried out for 2 hours at 165 - 180 °C. However, this last step is not absolutely necessary. After a few days, the casting compound reaches its final hardness even at room temperature (depending on the system).

- Electrical tests of the component quality can usually be carried out after the first curing (8 hours at room temperature or 1 h @ 100 °C).

Protection

Our products are intended solely for industrial use. For further details, please refer to the safety data sheet.

Processing

Our processing instructions please find here.

You have questions according to our resins and varnishes or want to send an inquiry?

Our product manager will be happy to help you.

Technical data

| Property | Unit of measure | Condition | Value | Test method |

|---|---|---|---|---|

| Mixing ratio | weight-% | 100:100 | ||

| Pot lilfe | min | 25 °C | 50-60 | |

| Curing time | h | 25 °C | 8 | |

| Curing time | h | 100 °C | 1 |

| Property | Unit of measure | Condition | Value | Test method |

|---|---|---|---|---|

| Density | g/cm³ | WEVOSIL 20201/60 A | 0.96-1.00 | |

| Density | g/cm³ | WEVOSIL 20201/60 B | 0.96-1.00 | |

| Viscosity | mPas | WEVOSIL 20201/60 B / 22 °C | 300-700 | |

| Viscosity | mPas | WEVOSIL 20201/60 A / 22 °C | 300-700 | |

| Mixture viscosity | 22 °C | 300-700 |

| Property | Unit of measure | Condition | Value | Test method |

|---|---|---|---|---|

| Thermal class | H | DIN EN 60085 | ||

| Glass transition temperature | °C | -110 | TMA | |

| Thermal conductivity | W/m*K | 0.2 | ISO 22007-2:2008 |

| Property | Unit of measure | Condition | Value | Test method |

|---|---|---|---|---|

| Dielectric strength | kV/mm | 23 | DIN EN 60243 | |

| Dielectric constant; at 1 kHz, 23 °C | 2.7 | DIN EN 60250 | ||

| Volume resistance specific at 23 °C, 50 % r.h. | Ωxcm | >10^14 | DIN EN 62631-3-1:2016 |