WEVOSIL high-performance potting compounds for superior thermal management and electrical insulation

WEVOSIL is a range of silicone-based materials developed for the highest resistance and thermal requirements of modern electronics. Modern electronic systems increasingly have to withstand extreme requirements: High temperatures, strong vibrations, aggressive chemicals and miniaturisation pose significant challenges - this is where the five key features of WEVOSIL potting compounds come into play.

Silicone-based potting materials from WEVOSIL at SynFlex

Maximum thermal conductivity, excellent shock absorption and reliable protection for sensitive electronics.

Exceptional flow behaviour, UV stability and electrical insulation for sensitive components.

Stable, highly thermally conductive materials, easy to apply - for efficient thermal management.

Do you have any questions about our products and would like to send us an enquiry?

Our product manager will be happy to help you.

5 features that make WEVOSIL potting compounds the first choice for modern electronics

1. Optimum thermal management possible with silicone potting compounds

With thermal conductivities of 0.2 to 4.0 W/m-K, WEVOSIL potting compounds and gap fillers offer solutions for effective thermal management. They enable efficient dissipation of heat loss, reduce hotspots and make a decisive contribution to ensuring the performance and service life of electronic components even at high power densities.

2. High resistance to external influences (silicones for demanding environments)

WEVOSIL silicones are highly resistant to moisture, UV light and chemicals. This outstanding chemical resistance ensures that your electronics remain permanently protected even under difficult conditions in automotive and industrial applications.

With hardnesses ranging from Shore 00 to Shore A 70 in the cured state, WEVOSIL gels and potting compounds have a super-soft consistency. This ensures excellent shock and vibration damping, reduces mechanical stresses on sensitive components and thus protects against premature failure. Due to their high transparency and lightfastness, the silicone gels can also be used for optical applications such as LED and sensor encapsulation.

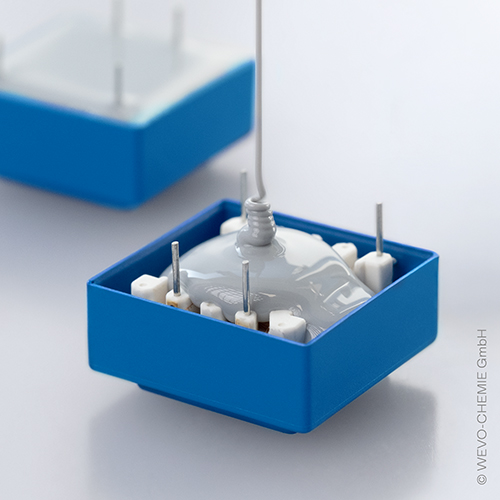

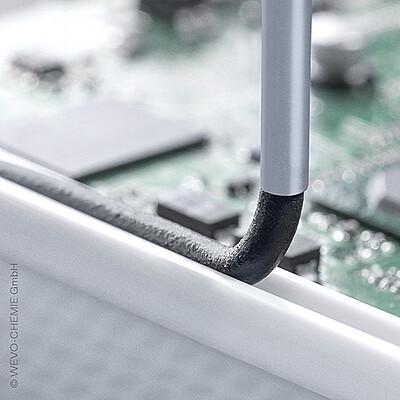

4. Flowable silicone formulations for precise processing

With viscosities from 300 to 5,000 mPa-s, WEVOSIL products offer excellent flowability despite a high degree of filling and enable reliable, process-safe processing even in narrow gaps and complex geometries. This facilitates processing in series production and contributes to process optimisation.

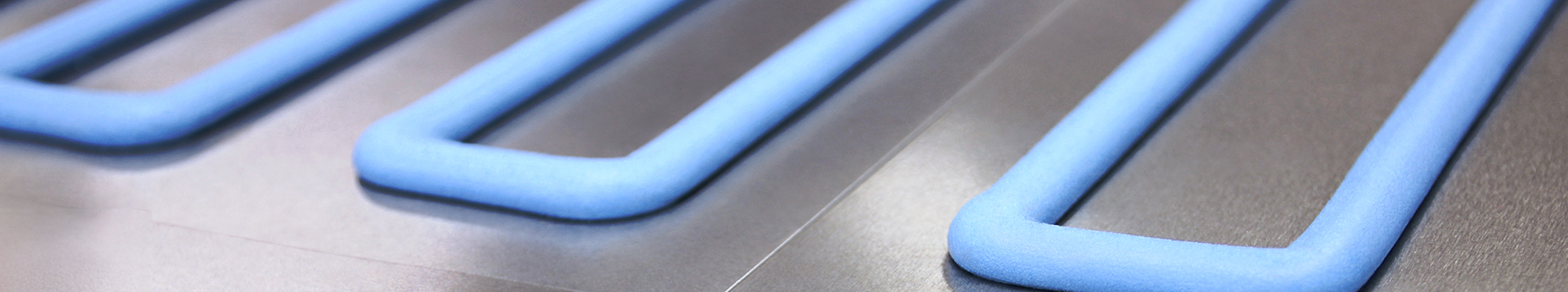

5. Silicone-based thermal interface materials for maximum heat dissipation

Our WEVOSIL gap fillers are specially designed as thermal interface materials (TIM) and offer thermal conductivities of up to 4.0 W/m-K and very low layer thicknesses of the thermal interface (<70 µm). They are ideal for applications where efficient heat transfer between components and heat sinks is crucial, for example in battery systems or power electronic modules.

The most important advantages of WEVOSIL silicones at a glance

- Temperature resistant from - 60 °C to +200 °C

- Shore hardness 00 to Shore hardness A 70

- Thermal conductivities from 0.2 to 4.0 W/m-K

- Flowable, process-safe formulations

- Outstanding chemical resistance

- Permanent elasticity and high elongation at break (>100 %)

- Excellent electrical insulation properties

- Flame retardant in accordance with UL 94 V-0 from a thickness of just 2 mm

Areas of application: Silicones for extreme requirements

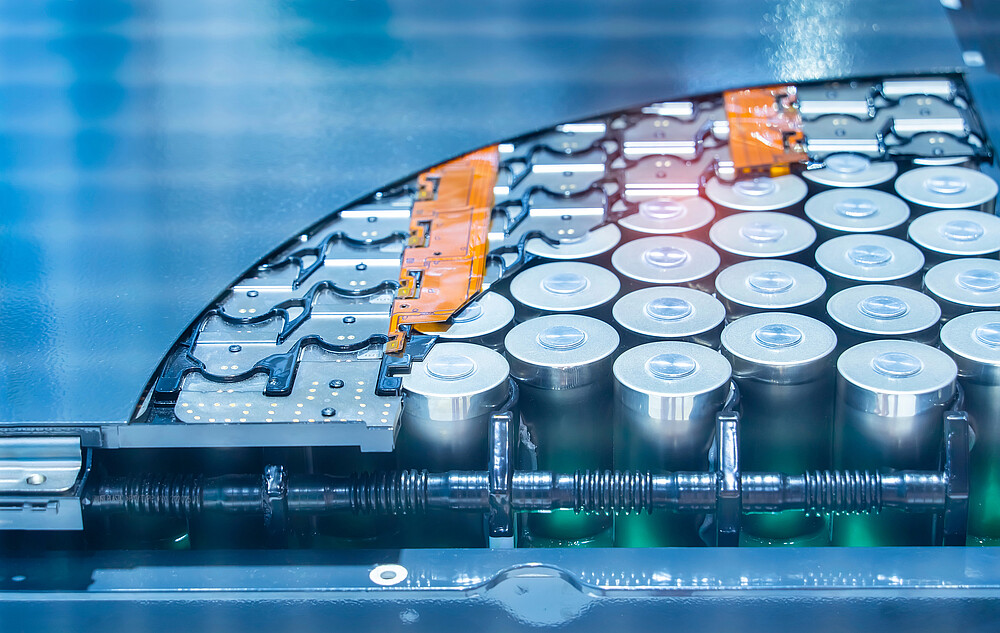

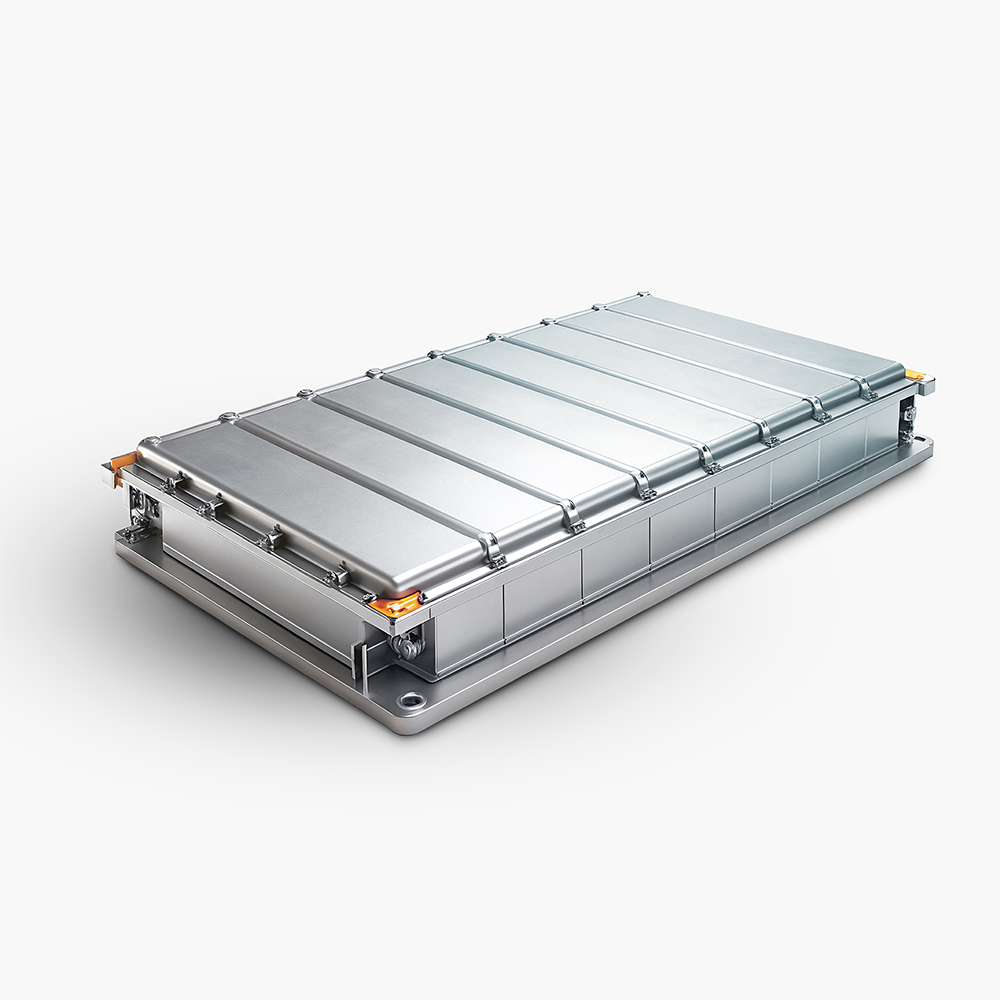

Battery systems

Prevent thermal chain reactions (thermal propagation) and increase the safety of high-voltage batteries in electric vehicles and stationary storage systems.

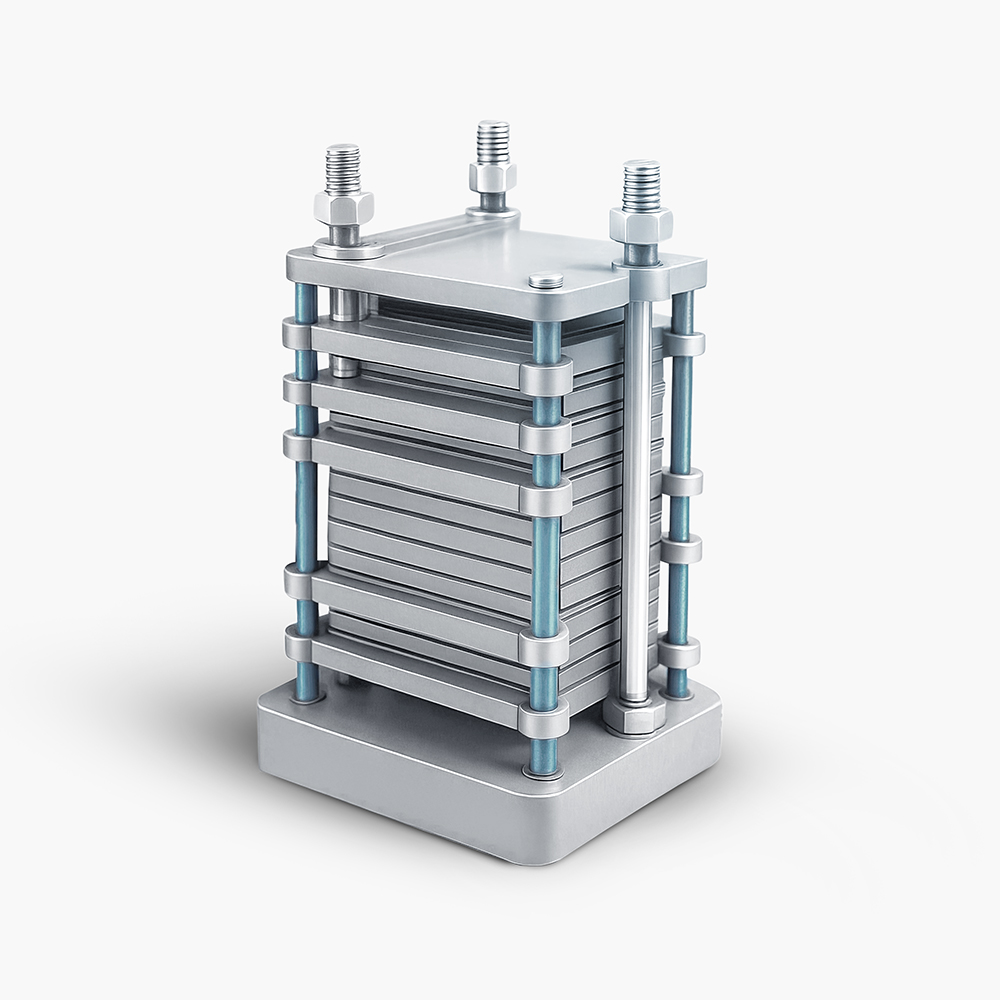

Fuel cell and electrolysis stacks

High-performance adhesives enable the greatest possible design freedom and safe operation even with aggressive media.

Power electronics

Protect onboard chargers, DC/DC converters and other electronic modules from heat, shock, moisture and chemical stress.

Stator encapsulation

Efficient insulation, mechanical protection and optimum thermal management for electric motors to maximise service life and efficiency.