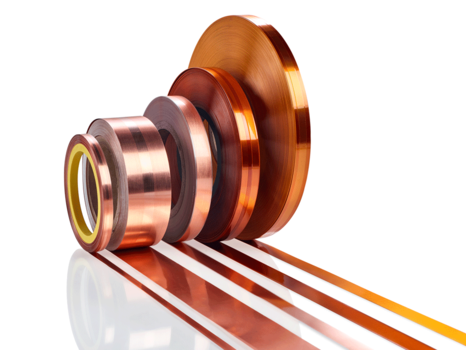

Copper foils

to protect electronic devices

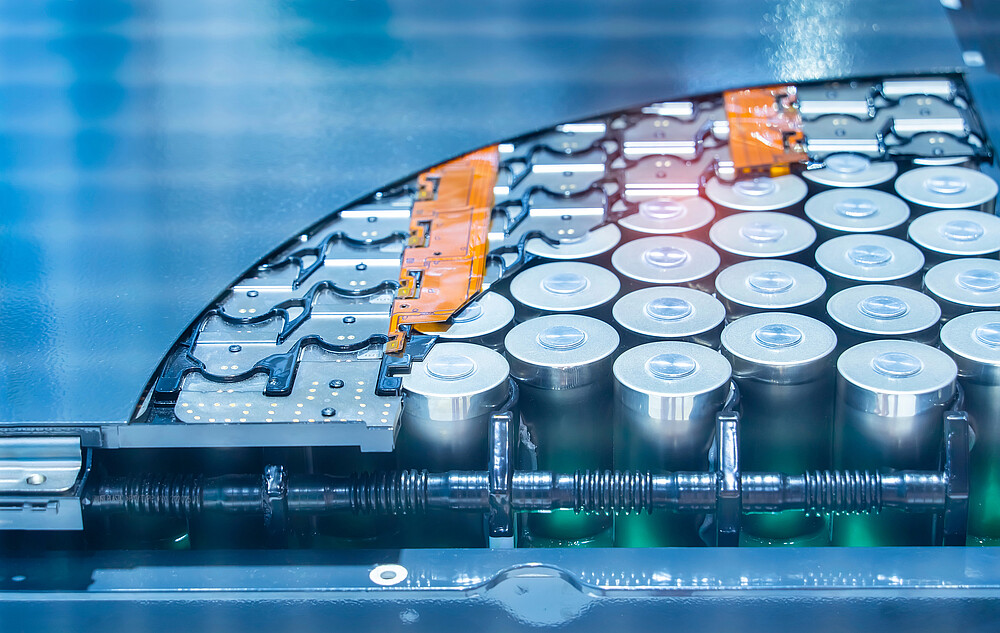

They also play a central role in the individual components that make them up. To ensure smooth operation, the electrical, magnetic or electromagnetic fields must be shielded and insulated from the components. Depending on the device, product-specific details are added, e.g. an aluminium foil instead of a copper foil. With our SynShield® product range, we offer you precisely these details and more.

Copper foil and surface insulating materials - requirements

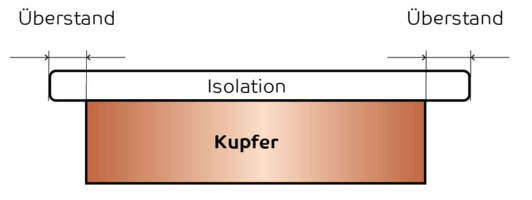

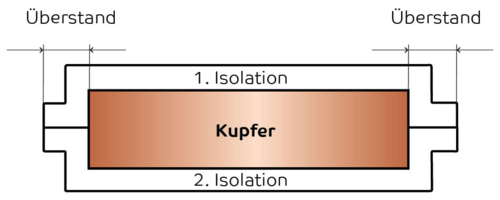

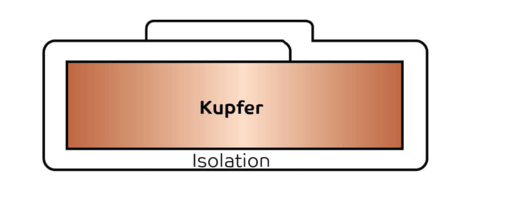

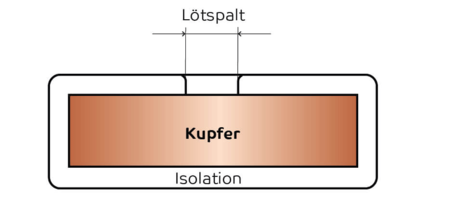

Depending on the project, our copper foils and insulation must fulfil different requirements. A selection of different thicknesses is available for this: 35, 50, 100, 150 and 200 μm. We cut the foil to the required width and then combine it with the appropriate surface insulation material of your choice. Depending on the desired material, we use one of two lamination processes:

A) The insulation is applied using a special process without adhesive. This process ensures excellent soldering behaviour and a low overall thickness.

B) The insulation is applied using an adhesive.

Do you have any questions about our copper and aluminium foils and would like to send us an enquiry?

Our product manager will be happy to help you.

Further fields of application for copper foil and aluminium foil

You benefit from the wide range of possible applications when you use our shielding foils in the following environments:

- Transformers

- coils

- inverters

- Interference suppression components in toroidal cores and chokes

- Signal and power transmission

As a long-standing producer, we are at your side with our technical experience in implementation - both aluminium foils and copper foils offer you advantages that we will be happy to discuss together.

When winding the copper foil, we also achieve a very high degree of flexibility, which enables small radii and an extremely compact design. In this way, components have a particularly high copper content and a high power density.

Quality assurance during isolation - the SynLab® supports you

Thanks to production at our site in Blomberg, we can offer you a connection to our own SynLab® test laboratory. The quality tests carried out in the laboratory during production guarantee the consistently high quality of your products. You can also choose to include SynShield® in an electrical insulation system by means of a short-term test (CCT).

Your advantages at a glance

- high flexibility - our foil can be wound tightly and therefore enables compact designs with more power

- Higher copper content, resulting in high power density

- Can also be used for signal or power transmission

- Can be incorporated into electrical insulation systems

Product programme

SynShield®