SynChem – Resins & Varnishes Synthite AC-43 Air drying varnish

Synthite AC-43 is a clear, air drying electrical insulation varnish on basis of modified polyester, suitable for class H.

Synthite AC-43 has the following excellent properties:

- UL-approved

- very fast air drying

- excellent chemical resistance

- solderable

- excellent adhesion

- good penetration

- transformer oil resistance ASTM D 155-55

- corrosion and humidity resistance

Application

Typical applications for Synthite AC-43 are:

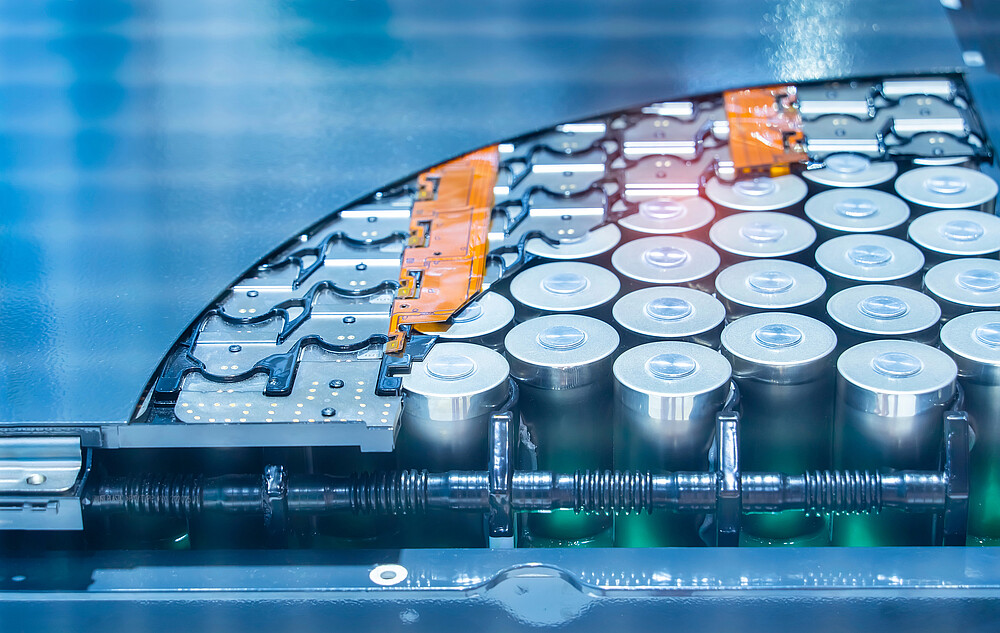

- stators

- printed circuit boards

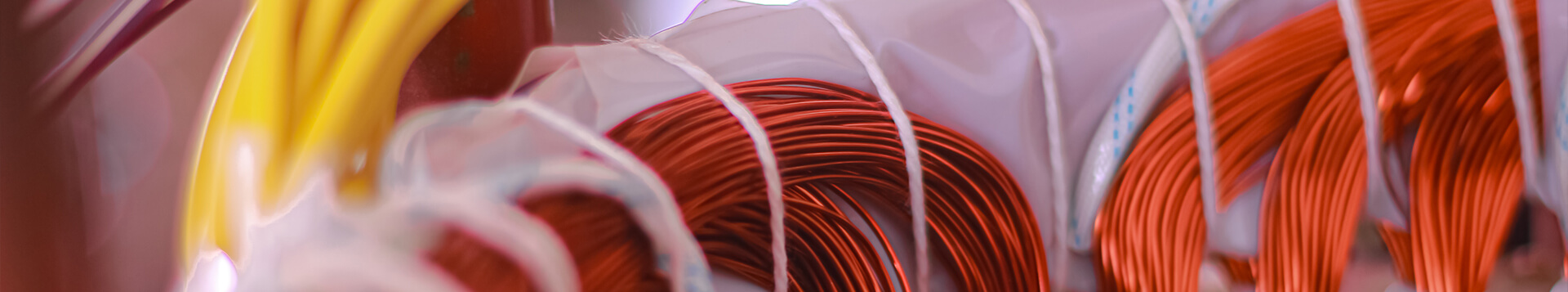

- form wound coils

- resistors

- transformers

- capacitors

Standards

Class H (180 °C) UL-file-no. OBOR2.E317427 and OBJS2.EB17429.

| Magnet wire | Twisted pairs | Helical coils |

| MW 24-C | 155 °C | 155 °C |

| MW 28-C | 130 °C | 130 °C |

| MW 35-C | 180 °C | 180 °C |

Delivery forms

Colour: clear

4.5 kg, 22.5 kg and spray bottles on request.

Storage

Synthite AC-43 can be stored at room temperature and in closed containers for up to 24 months (max. 30 °C). The varnish has to be stored in cold, dry places, protected against direct sunlight.

Hardening

Air drying time (on copper plate):

10 min. - set to touch

Protection

Use in well ventilated area, aboid contact with skin and eyes and wear protective clothes. Please observe the safety data sheet.

Processing

Synthite AC-43 may be applied by dipping, brushing or spraying as supplied.

For fast conveyor application, the following cycle is recommended:

1. Preheat units for 10 min. at 110 °C

2. Dip into the varnish for 30 sec.

3. Drain 10-20 min.

4. Bake 60-90 min. at 110 °C

For this type of cycle Synthite AC43 should be diluted 10-15 % with Dolph's® T-200 thinner.

You have questions according to our resins and varnishes or want to send an inquiry?

Our product manager will be happy to help you.

Technical data

| Property | Unit of measure | Conditions | Values | Test method |

|---|---|---|---|---|

| Coating thickness | µm | 75-100 | ASTM D-115-55 |

| Property | Unit of measure | Conditions | Value | Test method |

|---|---|---|---|---|

| Dielectric strength | kV/mm | dry / 25 °C | 80 | ASTM D-115 |

| Dielectric strength | kV/mm | after 24h water storage / 25 °C | 48 | ASTM D-115 |

| Creep resistance | CTI | 600 | IEC 60112 |

| Property | Conditions | Blistering | Rusting | Cracking | Test method |

|---|---|---|---|---|---|

| Resistance | Water | no | no | no | ISO 4628/2-3-4 |

| Resistance | 10 % Sulfuric acid | no | no | no | ISO 4628/2-3-4 |

| Resistance | 1 % Sodium hydroxide | no | no | no | ISO 4628/2-3-4 |

| Resistance | Salt water | no | no | no | ISO 4628/2-3-4 |

| Property | Unit of measure | Conditions | Values | Test method |

|---|---|---|---|---|

| Viscosity | s | 25 °C | 50-70 | ISO Cup 4 |

| Viscosity | s | 25 °C | 18-24 | Ford Cup 4 |

| Specific density | g/cm³ | 25 °C | 0.87-0.93 |