- individual films (type and thickness) available ex stock

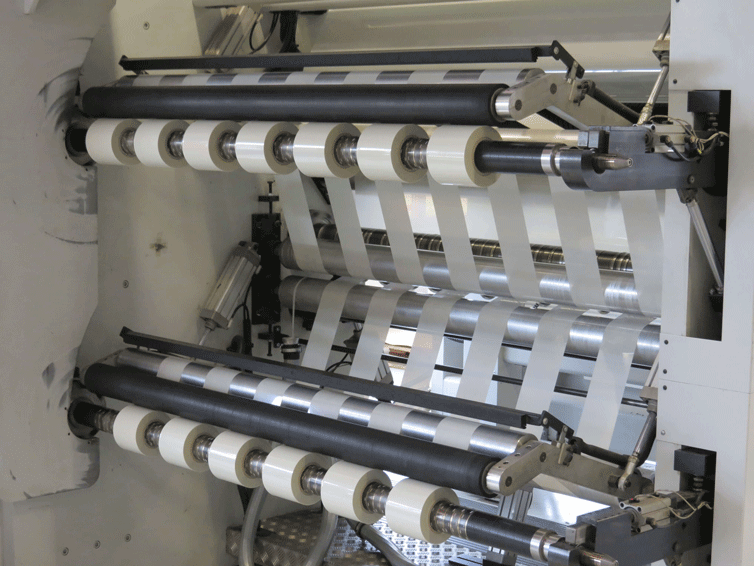

- modern machinery for the individual production of insulating materials according to your specifications

- fast sampling process

Electrical insulation materials – increase the service life of your electrical components

Electrical insulation materials make your electrotechnical products safe and enable permanent isolation of voltage from the environment.

Depending on the area of application, you can use different types of electrical insulating materials. Whether insulating materials based on PET, PEN and PI films, sulphate pulp or meta-aramide - use only these materials or a combination that we make available to you as so-called multi-layer insulating materials.

Benefit from our many years of know-how in the production and sale of customized solutions made of laminates and individual stamped parts - we offer you the highest product quality, respond to your needs and support you in the selection of your electrical insulation materials.

Do you need electrical insulation systems tailored to your electrotechnical products? In our product range, you will find insulating sleevings, adhesive tapes, insulated connection cables, impregnating agents, individual punched parts and winding tapes in addition to the insulating materials. We can combine these in a coordinated manner to create a suitable electrical insulation system - and thus ensure the best possible insulation of your electrotechnical product.

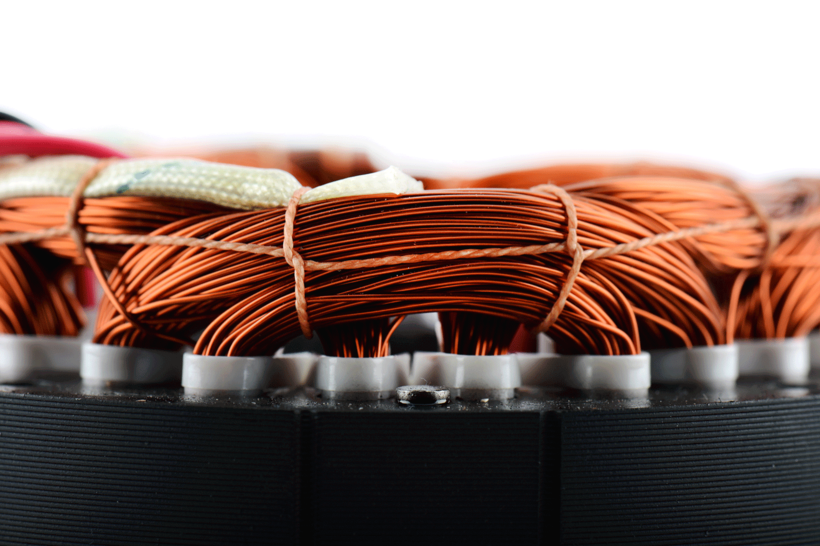

![[Translate to Englisch:] Isolierende Materialien eines Elektromotors](/fileadmin/_processed_/3/c/csm_Fotolia_53477191_XXL_012f9515bc.png)

You have questions according to our electrical insulation materials or want to send an inquiry?

Our sales representative will be happy to help you.

Our electrical insulation materials for your electrical components

In order to protect your electrical components over a long period of time, we offer you a wide range of insulating materials, electrical adhesive tapes and electrical insulating sleevings.

Our insulating materials of the SynTherm® product line provide the largest range. Outstanding are individual solutions of multi-layer laminates such as SynTherm® APA or SynTherm® AHA and the aramide paper SynTherm® YT produced at our locations in Blomberg and Shanghai. Also films, pressboards and special products such as SynTherm® YT510 crepe tube offer your components optimum electrical insulation properties.

Our SynTape® range includes electrical adhesive tapes made of a variety of carrier materials such as polyester, polyimide or PTFE in combination with various types of adhesives.

You are looking for customized solutions that meet both the properties of our SynTherm® and our SynTape® product line? Our SynPrep range offers individually punched parts made of adhesive and non-adhesive insulating materials.

The segment Insulate is completed with our range of electrical insulating sleevings SynSleeve and the SynChem impregnants & potting compounds.

Thanks to their outstanding properties, you can use the products in a wide range of industries and applications. Whether you need an individual solution or a customized stamped part - you are guaranteed to find the right product for your application with us.

Your benefit provided by SynFlex electrical insulating materials

If you are looking for high quality, customized multi-layer surface insulating materials and stampings, you have come to the right place. We have been in the electrical insulation industry for years and know how to manufacture your products to meet your requirements and exceed your expectations. In doing so, we offer you the following advantages.

High application competence

We support you in the development of your project and help you select suitable materials for your electrical insulation system.

Product quality and quality assurance

Our certified laboratory ensures the product quality of your electrical insulation material.

- large laboratory with extensive testing facilities (IR, TGA etc.)

- laboratory services according to UL 1446 (experience in long-term tests and ageing behaviour of materials)

- technical consulting competence provided by specialized product managers

Decades of production experience and expertise

Use our experience in the production of laminates and stamped parts for your project and benefit from our decades of know-how.

- from the starting material to the individual stamped part

- multi-layer coating and lamination

- individual die-cutting, bending and forming (samples available at short notice)

- tape cutting, rolls

Directly available stock and production capacity

Our international network offers you consistent quality of our services and products.

- large selection of standard materials such as PI, PEN and PET films, aramide paper, casting resins and potting compounds from reliable brand manufacturers

- risk minimization due to alternative product variants

- international footprint in Europe, Middle East and Asia

Insulating Materials

Insulating materials are used in electrotechnical and electronic applications for electrical insulation and mechanical protection.

see insulating materials

Electrical adhesive tapes

Electrical adhesive tapes are used for electrical insulation, mechanical protection as well as for fixing, masking, labelling, bundling and marking.

see electrical adhesive tapes

Electrical insulating sleeving

SynFlex supplies its sleeves in rings, on spools, in drums or as sections - individually according to customer requirements. From an inner diameter of 0.5 mm they can be delivered within 24 hours.

see electrical insulating sleevings

Resins & varnishes

In the winding industry, impregnating agents are used to solidify the windings and protect them from external influences such as moisture, dust or chemicals. For the protection of the environment and employees, we use extremely compatible impregnants.

see resins and varnishes

Stamped & shaped components

![[Translate to Englisch:] SynPrep Stanzteile aus SynTherm® Materialien](/fileadmin/_processed_/b/4/csm_SynPrep_Still_Stanzteile_01_0fb2cad64b.png)

The range of SynPrep stamped and shaped components is very comprehensive and offers individual product solutions in perfection. The products are used for covering, insulating, protecting, underlaying and insulating.

see stamped and shaped components

Wrapping tapes

The product group SynWrap contains various winding tapes which are used for taping, winding and insulating components in electrical engineering. The most common application is the taping of winding heads in electric motors. In addition, winding tapes are used to fix components in electric motors and transformers.

see wrapping tapes

You have questions according to our electrical insulation materials or want to send an inquiry?

Our sales representative will be happy to help you.

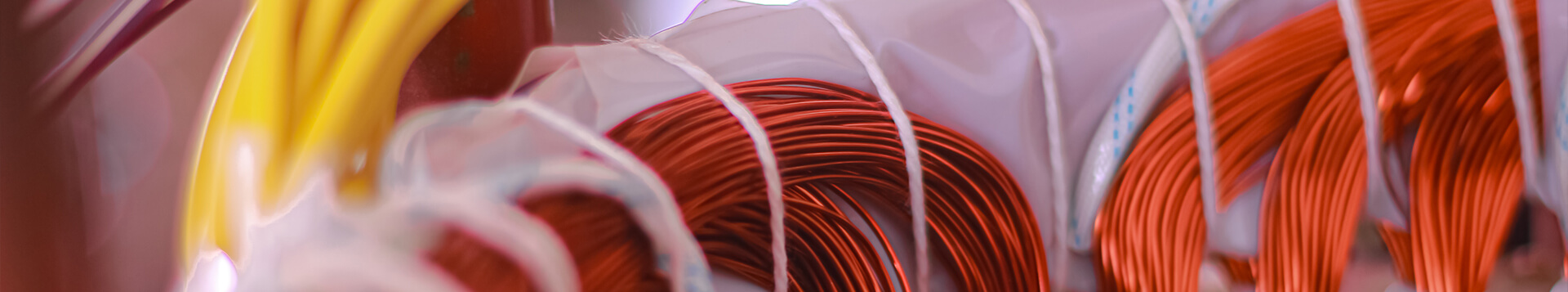

![[Translate to Englisch:] SynTherm® Flächenisolierstoffe](/fileadmin/_processed_/9/c/csm_SynTherm_Synflex_26021846798_6bf32efdeb.png)

![[Translate to Englisch:] SynTape® Elektroklebebänder](/fileadmin/_processed_/e/3/csm_SynTape_Synflex_Still_Kleberollen_01_ef173ee4e9.png)

![[Translate to Englisch:] SynSleeve Elektroisolierschläuche](/fileadmin/_processed_/9/7/csm_SynSleeve_F_GS_UL-2Komma10_Rolle_333b093ef4.png)

![[Translate to Englisch:] SynWrap Wickelbänder](/fileadmin/_processed_/9/e/csm_SynTherm_Krepp_0768_a37f5c331d.png)