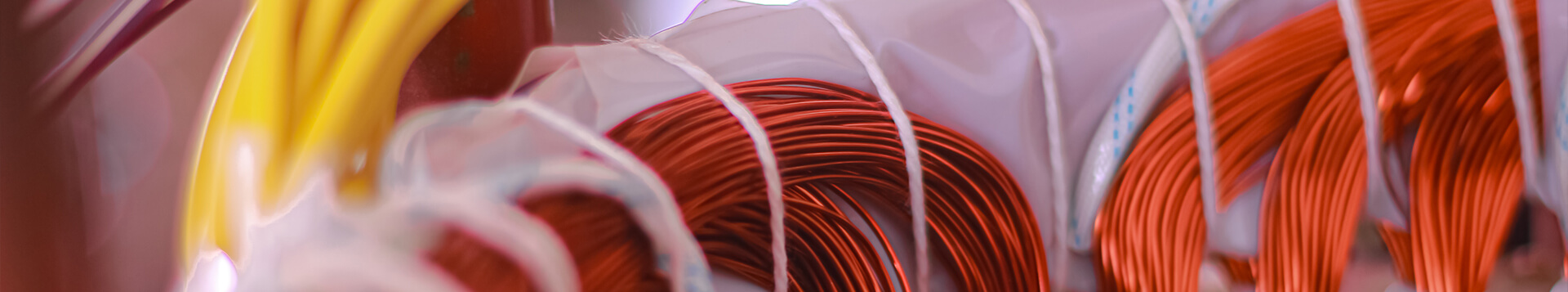

SynChem – Resins & Varnishes Dolphon® XL-2112 single-component resin

Dolphon® XL-2112 is a low emission single-component resin based on polyester.

Dolphon® XL-2112 has the following known properties:

- UL-approved

- excellent wetting properties

- good bond strength

- very low weight loss on cure

- very low odour

- relatively fast cure cycles

- medium-low viscosity

Application

Dolphon® XL-2112 is a proven resin for impregnating large stators, rotors, transformers and coils, even in very demanding applications with impact loads.

Standards

- UL-approved class H (180 °C), File OBOR2.E317427 and

OBJS2.E317429. - UL-System-approved 180 °C (H)

- UL-approved with magnet wire

- temperature class acc. UL 1446:

| magnet wire | Twisted pairs |

| MW 16-C | 220 °C |

| MW 35-C | 200 °C |

Delivery forms

Dolphon® XL-2112 is available in 25 kg disposable containers, 230 kg barrels and 1,200 kg containers.

Storage

Dolphon® XL-2112 can be stored for 18 months at room temperature in a sealed container (max. 30 °C). The impregnating resin must be stored in a cool place and protected against direct sunlight, UV radiation and sources of heat.

Hardening

The curing time commences once the object temperature has been reached.

Typical curing times (minimum):

- 1 h - at 150 °C*

- 3-4 h - at 130 °C*

- 5-7 h - at 120 °C

*Full curing is measured by DSC. Time must be taken after units reach the baking temperature. For objects having to endure high mechanical or chemical stress during service, longer curing times are recommended.

Processing

Dolphon® XL-2112 can be processed in dipping plants and vaccum chambers.

Dolphon® XL-2112 is sensitive to UV-rays. When not in use, the impregnation tanks must be protected from the light by means of a (non-transparent) lid.

Suggested impregnating process:

- Preheat the units at 50-60 °C (max.)

- Dip into the resin for 30-60 min.

- Drain for 1 h min.

- Bake at:* (see curing)

For the VPI application the cycle must be set for each type of machines. Feel free to contact us.

You have questions according to our resins and varnishes or want to send an inquiry?

Our product manager will be happy to help you.

Technical data

| Property | Unit of measure | Conditions | Values | Test method |

|---|---|---|---|---|

| Gel time | min | at 100 °C | 30-50 | |

| Weight loss | % | 10 g backed 1 h at 150 °C | <3.5 | |

| Bond strength | N | 25 °C | ˃130 | IEC 61033 Helical Coil |

| Bond strength | N | 80 °C | ˃82 | IEC 61033 Helical Coil |

| Bond strength | N | 155 °C | ˃45 | IEC 61033 Helical Coil |

| Property | Unit of measure | Values | Test method |

|---|---|---|---|

| Thermal conductivity | W/mK | 0.25-0.30 | |

| Thermal class | °C | 200 | MW 35-C /UL 1446 |

| Thermal class | °C | 220 | MW16-C / UL 1446 |

| Property | Unit of measure | Conditions | Value | Test method |

|---|---|---|---|---|

| Reaction with natural rubber | yes | |||

| Resistance | Xylene, Methanol, Hexane | resistent | IEC 60464-2 | |

| Resistance | % | transformer oil | <0.5 | ISO 175 - 7 days |

| Resistance | % | 30 % sulfuric acid | <1.5 | ISO 175 - 7 days |

| Resistance | % | 10 % hydrochloric acid | <2.5 | ISO 175 - 7 days |

| Water absorption | % | 90 min. at 100 °C | <1.5 | ASTM D 570 |

| Water absorption | % | 24h at 23 °C | <1 | ASTM D 570 |

| Property | Unit of measure | Conditions | Values | Test method |

|---|---|---|---|---|

| Dielectric strength | kV/mm | 0.025 mm film / 25 °C | >128 | ASTM D-115. RT |

| Dielectric constant | at 25 °C / 50 Hz | 3.2 | ASTM D-150 | |

| Volume resistivity | Ω x cm | 25 °C | >10^15 | IEC 60464-2 |

| Volume resistivity | Ω x m | after 7 d water immersion | >10^12 | IEC 60464-2 |

| Property | Unit of measure | Conditions | Values | Test method |

|---|---|---|---|---|

| Specific density | g/cm³ | at 25 °C | 1,12-1,18 | |

| Viscosity | mPas | 25 °C | 1700-2000 | Brookfield |

| Specific density | g/l |