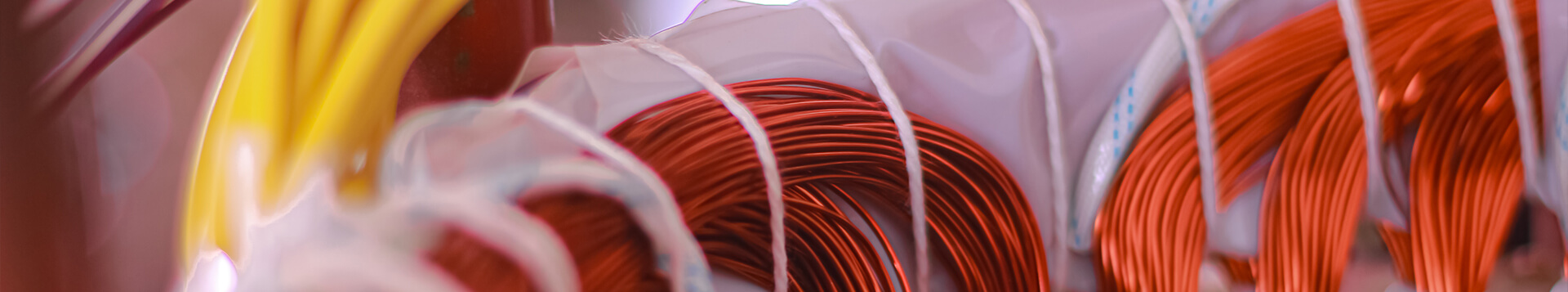

SynChem – Resins & Varnishes Voltatex® 4204 1-component impregnating resin

Voltatex® 4204 is a low emission, environmentally friendly, ready-to-use impregnating, yellowish 1K dip resin based on unsaturated polyesterimide resins.

- single component

- low emission

- very low viscosity

- environmentally friendly

- minimum exposure in the working area

- no risk of fire or explosion

- based on renewable raw materials

The cured resin compound is characterised by:

- very low tendency to crack

- very good adhesion

Application

- electric motors

- generators, also for large drives

- transformers

- in particular for mica tape insulated flat rolled litz wires

- suitable for: insulation systems of thermal class 180 (H)

- suitable for applications in medium and high voltage area

Standards

- UL approved, file no.: E 101752 (M) Unterwriters Laboritories Inc., USA

- Temperature Index 180 (H) in acc. with IEC 60085

- UL 1446 approved:

| Twisted Pair | ASTM D2307 | MW 35:180 |

| MW 80:155 | ||

| Helical Coil | ASTM D2519 | MW 35:200 |

| MW 80:180 |

Delivery forms

Voltatex® 4204 is supplied in one-way-cans containing 25 kg or 200 kg.

Storage

The resin can be stored for up to 8 months at max. 25 °C if sealed correctly in original containers. Opened containers have to be resealed and protected against direct sunlight!

Hardening

Voltatex® 4204 is a low emission product, nevertheless to minimize evaporation of reactive components during curing; the impregnated objects should be heated up to curing tempera-ture in the shortest possible time. The air flow in the curing oven should also be kept to the minimum permitted by safety considerations.

Curing times:

| Dip & Bake Process | 130 °C | 0.5-1 h |

| 150 °C | 15-30 min. | |

| Trickle Feed Process | 130 °C | 15-20 min. |

| 150 °C | 10-15 min. |

Protection

Cured Voltatex® 4204 is biologically inactive and not dangerous to health. When processing the liquid resin, please refer to the Material Safety Data Sheet (MSDS) for Voltatex® 4204.

Cleaning

Cured Voltatex® 4204 is almost insoluble. Therefore, application equipment should be regularly cleaned with cleaner Voltatex® T050. All equipment cleaning and maintenance should be carried out in accordance with the equipment manufacturers instructions.

Processing

The impregnating resin can be applied by using

- all kind of conventional dip & bake equipment

- continuous, vacuum dip and VPI processes

- dip & roll equipment

- trickle feed machines

Unlimited tank stability with resin Voltatex® 4204 can be achieved as long as the material is kept below 25 °C and at least 20 % of the tank content is used and replaced with fresh resin per month.

You have questions according to our resins and varnishes or want to send an inquiry?

Our product manager will be happy to help you.

Technical data

| Property | Unit of measure | Values | Test method |

|---|---|---|---|

| Bond strength of twisted coils room temperature | N | 200 ± 40 | IEC 60455-2, test method A acc. IEC 61033 |

| Bond strength of twisted coils 155 °C | N | 57 ± 10 | IEC 60455-2, test method A acc. IEC 61033 |

| Shore D hardness room temperature | 70 ± 5 | IEC 60455-2, test method acc. ISO 868 | |

| Water absorption | % | 0.6 | Company standard Energy Solutions-015, acc. ISO 62 |

| Glass transition temperature | °C | 55-75 | DSC-method |

| Volume shrinkage | % | Company standard Energy Solutions-003 |

| Property | Unit of measure | Conditions | Values | Test method |

|---|---|---|---|---|

| Resistance | solvent vapours | under test | IEC 60455-2, test method acc. ISO | |

| VOC acc. 31. BlmSchV | % | 0.8 | 2010/75/EU | |

| Resistance | Distilled water, transformer oil | resistant | company standard Energy Solutions - Voltatex® 019 |

| Property | Unit of measure | Typ. values | Test method |

|---|---|---|---|

| Dielectric strength at 23 °C and 50 % r.h. | kV/mm | 60-85 | IEC 60455-2, test method acc. IEC 60243-1 |

| Dielectric strength at 155 °C | kV/mm | 55-80 | IEC 60455-2, test method acc. IEC 60243-1 |

| Dielectric strength at 23 °C after 96 h storage at 92 % r.h. | kV/mm | 35-75 | IEC 60455-2, test method acc. IEC 60243-1 |

| Dielectric strength at 105 °C after 168 h oil immersion | kV/mm | 70-110 | IEC 60455-2, test method acc. IEC 60243-1 |

| Specific volume resistance at 180 °C | Ω*cm | 10^11-10^12 | IEC 60455-2, test method acc. IEC 60093 |

| Specific volume resistance after 7 d water immersion | Ω*cm | 10^14-10^16 | IEC 60455-2, test method acc. IEC 60093 |

| Creep resistance | CTI 600 M | IEC 60455-2, test method acc. IEC 60112 | |

| Dielectric constant at 23 °C between 50 Hz and 1 MHz | 3.9 ± 0.4 | IEC 60455-2, test method acc. IEC 60250-1 | |

| Loss factor at 155 °C and 50 Hz | 140x10^-3 - 200x10^-3 | IEC 60455-2 | |

| Loss factor cross section 0.2=200x10^-3 | °C | 150-180 | IEC 60250, between 50 Hz and 1 MHz |

| Property | Unit of measure | Conditions | Values | Test method |

|---|---|---|---|---|

| Impact on enamelled wires | compatible with all common magnet wires | IEC 60851-4 | ||

| Viscosity | mPas | at 25 °C | 315 ± 25 | DIN 53019 |

| Viscosity | mPas | at 40 °C | 130 ± 25 | DIN 53019 |

| Reaction process gel time | min | 100 °C | 9.6 | company standard Energy Solutions-014 |

| Reaction process reaction time | min | 100 °C | 11.6 | company standard Energy Solutions-014 |