SynTherm® – Insulating Materials SynTherm® YT56 DDP

SynTherm® YT56 DDP is a synthetic medium density electro insulation paper constructed of a calendered, aromatic polyamide fibride flock composition. Both sides of the paper are printed with a B-stage epoxy resin in a diamond dotted pattern.

The base material SynTherm® YT56 is a Class H (180 °C) insulating material. Its mechanical, thermal and electrical properties are between SynTherm® YT510 and SynTherm® YT511.

Temperatures over 200 °C only slightly influence its electrical properties. The good mechanical properties can be extrapolated to significantly higher temperatures. SynTherm® YT56 is also suitable for use at temperatures to -190 °C due to its polymer-structure.

It has a high short-term dielectric strength. SynTherm® YT56 is compatible with all classes of common resins, varnishes, adhesives as well as transformer liquids, lubricants, and cooling agents. Common solvents may lead to slight reversible moisture expansion. SynTherm® YT56 has low flammability (UL 94V-0) and very high resistance to beta and gamma radiation.

Application

SynTherm® YT56 DDP is designed for cost critical applications which require a moderate mechanical and electrical strength.

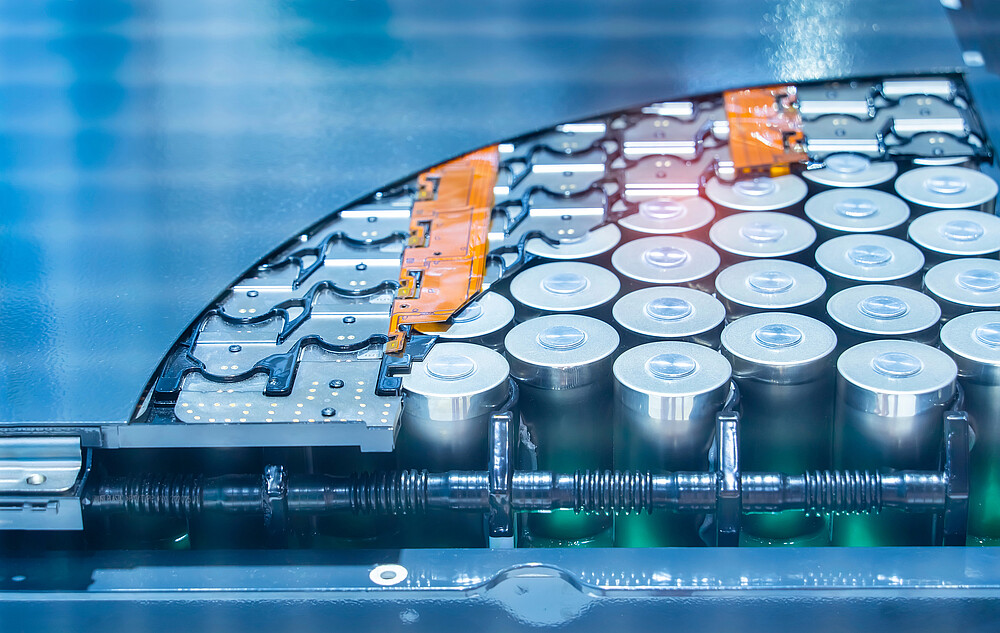

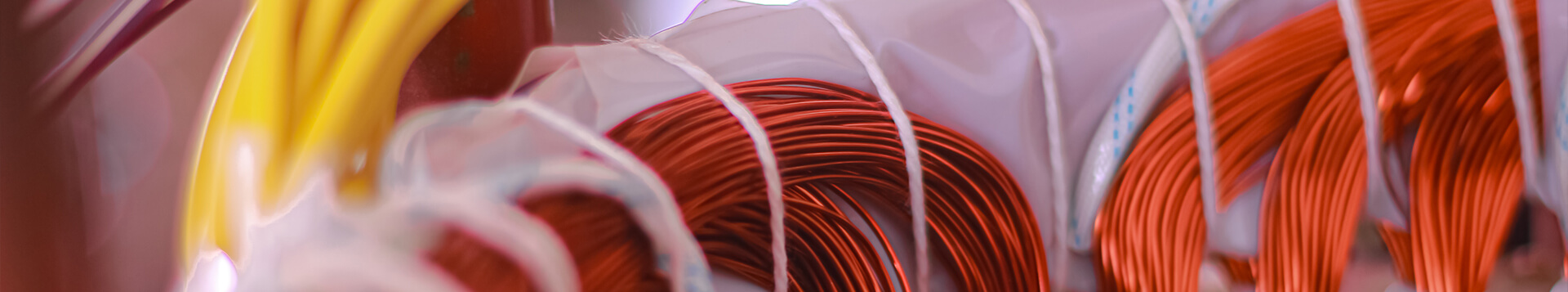

SynTherm® YT56 DDP is used as layer insulation in transformers.

Standards

- Insulating material class F (155 °C). Base material class H (180 °C)

- The base material is UL listed (RTI mech. + electr. 210 °C)

Delivery forms

Film thickness in μm:

130, 180, 250, 300, 510, 760

SynTherm® YT56 DDP is available:

- in tapes: depending on material thickness on request

beginning at 6mm (thin material)

- in rolls: 1000 mm

Feathering:

- depth approx. 1 - 12 mm, distance approx. 1 - 10 mm

- 10 mm up to 240 mm tape-width, thickness on request

Base

Calandered, aromatic polyamide fibride flock composition with diamond dotted B-stage resin on both sides.

Punched parts, bent & formed parts

We offer a wide range of punched and formed parts: Rolls, individual parts unsorted, sorted or stacked, adhesive on one or both sides, non-adhesive, with or without a grip tab.

You have questions according to our electrical insulation materials or want to send an inquiry?

Our product manager will be happy to help you.

Technical data

| Property | Unit of measure | Test method | ||||||||

|---|---|---|---|---|---|---|---|---|---|---|

| Nominal thickness | μm | 130 | 180 | 250 | 300 | 380 | 510 | 610 | 760 | |

| Typical thickness | µm | 130 | 180 | 250 | 300 | 380 | 520 | 610 | 760 | GB/T12914-2008 |

| Specific weight | g/m² | 86 | 125 | 172 | 245 | 265 | 342 | 414 | 532 | GB/T451.2-2002 |

| Tensile strength longitudinal | N/cm | 100 | 155 | 200 | 300 | 260 | 320 | 375 | 420 | GB/T12914-2008 |

| Tensile strength transversal | N/cm | 40 | 60 | 80 | 145 | 130 | 150 | 180 | 200 | GB/T12914-2008 |

| Elongation at break longitudinal | % | 8 | 9 | 9.5 | 12 | 10.5 | 11 | 11 | 10 | GB/T12914-2008 |

| Elongation at break transversal | % | 8.5 | 9.5 | 10 | 13 | 11 | 11.5 | 10.5 | 10 | GB/T12914-2008 |

| Elmendorf tear strength longitudinal | N | 1.5 | 2.5 | 3 | 5.5 | 8.5 | 11.5 | N/A | N/A | GB/T455-2002 |

| Elmendorf tear strength transversal | N | 3.5 | 5 | 6 | 7 | 12.5 | 14.5 | N/A | N/A | GB/T455-2002 |

| Property | Unit of measure | |||||

|---|---|---|---|---|---|---|

| Thickness increase (one side) | µm | 10±15 % | ||||

| Basic weight increase (both sides) | g/m² | 5±10 % | ||||

| Curing conditions | h | 1 | 3 | 10 | 20 | 30 |

| Curing conditions | °C | 130 | 120 | 110 | 100 | 90 |

| Shelf life | 6 months after production |

| Property | Unit of measure | Test method | ||||||||

|---|---|---|---|---|---|---|---|---|---|---|

| Nominal thickness | μm | 130 | 180 | 250 | 300 | 380 | 510 | 610 | 760 | |

| Field intensity | kV/mm | 11 | 11 | 12 | 15 | 12 | 13 | 13 | 13 | GB/T1408.1-2006 |