SynChem – Resins & Varnishes Voltatex® 4230 1-component-resin

Voltatex® 4230 is a low emission, ready-to-use impregnating, yellowish 1K dip resin based on unsaturated polyesterimide resins.

- single component

- low emission

- minimum exposure in the working area

- excellent impregnating result and high efficiency due to structural-viscose behaviour

The cured resin compound is characterised by:

- low tendency to crack

- very good adhesion

- good elasticity

- high thermal and mechanical strength, even under extreme long-term stress

Application

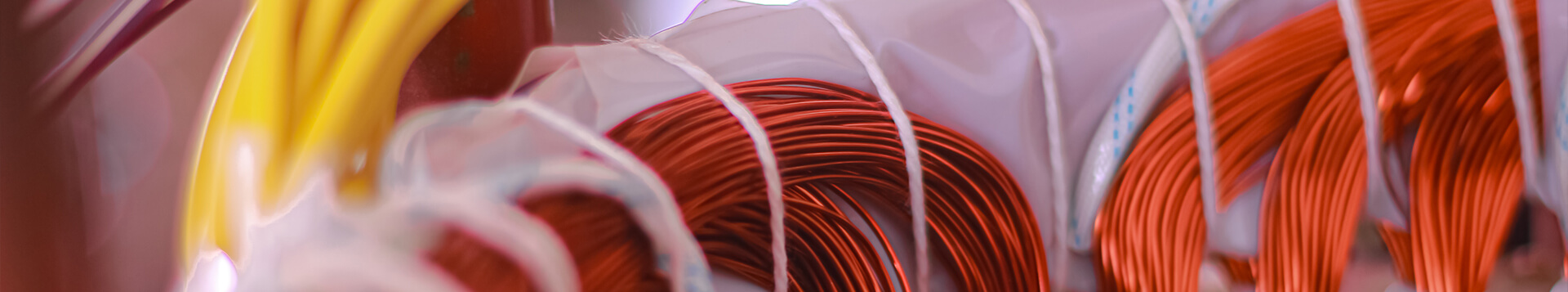

- electric motors, also for large drives

- transformers, especially with thick wires and shaped conductors

- suitable for: insulation systems of thermal class 220 (R)

Standards

- Insulating systems up to thermal class H acc. to IEC 60085

- Temperature index according to IEC 60455-3-5: Type 220

- UL listed, file no.: E 101752 (M)

- Polybrominated diphenylether 2003/11/EU

- UL approved with enamelled Cu wire

Temperature class according

| Twisted Pair | ASTM D2307 | MW 30:200 |

| MW 35:220 | ||

| Helical Coil | ASTM 2519 | MW 30:240 |

| MW 35:220 |

Electrical insulation systems according to UL 1446 (IEC 61858):

| Class 130 | C190HE |

| R150HE | |

| Z130HE | |

| Z150HE | |

| Class 155 | C290HE |

| CZ255HE | |

| R201HE | |

| R203HE | |

| Z200HE | |

| Class 180 | R342HE |

| R342HE2 |

Delivery forms

Voltatex® 4230 is supplied in one-way-cans containing 25 kg. Additionally 1000 kg containers (returnable) are available (not for oversea export).

Storage

The resin can be stored for up to 4 months at max. 25 °C if sealed correctly in original containers. Opened containers have to be resealed and protected against direct daylight!

Hardening

Voltatex® 4230 is a low emission product, nevertheless to minimize evaporation of reactive components during curing; the impregnated objects should be heated up to curing temperature in the shortest possible time. The air flow in the curing oven should also be kept to the minimum permitted by safety considerations.

Curing times (Dip & Bake Process):

at 130 °C: 2h

at 150 °C: 1h

Protection

Cured Voltatex® 4230 is biologically inactive and not dangerous to health. When processing the liquid resin, please refer to the Material Safety Data Sheet (MSDS) for Voltatex® 4230.

Cleaning

Cured Voltatex® 4230 is almost insoluble. Therefore, application equipment should be regularly cleaned with cleaner Voltatex® T050. All equipment cleaning and maintenance should be carried out in accordance with the equipment manufacturer’s instructions.

Processing

The impregnating resin can be applied by using:

- all kind of conventional dip & bake equipment

- continuous and vacuum dip processes

- VPI process

Voltatex® 4230 generally offers specific advantages such as very low evaporation losses in impregnating tanks, high resin retention on impregnated objects and low draining losses while curing. Related to the structural-viscose behaviour the resin requires convection prior to the impregnating process in order to provide a reasonable penetration into the winding.

Unlimited tank stability with resin Voltatex® 4230 can be achieved as long as the material is kept below 25 °C and at least 20 % of the tank content is used and replaced with fresh resin per month.

Technical data

| Property | Unit of measure | Values | Test method |

|---|---|---|---|

| Bond strength of twisted coils room temperature | N | 240 ± 30 | IEC 60455-2, test method A acc. IEC 61033 |

| Bond strength of twisted coils 130 °C | N | 80 ± 15 | IEC 60455-2, test method A acc. IEC 61033 |

| Bond strength of twisted coils 155 °C | N | 70 ± 15 | IEC 60455-2, test method A acc. IEC 61033 |

| Bond strength of twisted coils 180 °C | N | 55 ± 10 | IEC 60455-2, test method A acc. IEC 61033 |

| Shore D hardness room temperature | 80 ± 5 | IEC 60455-2, test method acc. ISO 868 | |

| Water absorption | % | 0.3-0.7 | IEC 60455-2, test method 1 acc. ISO 62 after 96h at 23 °C |

| Property | Unit of measure | Values | Test method |

|---|---|---|---|

| Temperature index | °C | 220 | IEC 60455-3-5, test method acc. IEC 60216 |

| Bond strength IEC 60317-8 | °C | MW 30: 238 | IEC 61033, method B, final point 22 N |

| Bond strength IEC 60317-13 | °C | MW 35: 229 | IEC 61033, method B, final point 22 N |

| Testing voltage IEC 60317-8 | °C | MW 30: 212 | IEC 60172 |

| Testing voltage IEC 60317-13 | °C | MW 35: 222 | IEC 60172 |

| Thermal conductivity | W(m*k)^-1 | 0.23 | acc. DIN 51046 |

| Property | Conditions | Values | Test method |

|---|---|---|---|

| Resistance | transformer oil, distilled water, 5 % soap-dilution | resistant | IEC 60455-2, test method acc. ISO 175 |

| Resistance | Hexane, methanol, actone, xylene | resistant | company standard Energy Solutions 019 |

| Property | Unit of measure | Condition | Values | Test method |

|---|---|---|---|---|

| Dielectric strength at 23 °C and 50 % r.h. | kV/mm | 100-125 | IEC 60455-2, test method acc. IEC 60243-1 | |

| Dielectric strength at 155 °C | kV/mm | 75-110 | IEC 60455-2, test method acc. IEC 60243-1 | |

| Dielectric strength at 23 °C after 96 h storage at 92 % r.h. | kV/mm | 75-100 | IEC 60455-2, test method acc. IEC 60243-1 | |

| Dielectric strength at 105 °C after 168 h oil immersion | kV/mm | 95-145 | IEC 60455-2, test method acc. IEC 60093 | |

| Specific volume resistance at 155 °C | Ω*cm | 10^9 - 10^11 | IEC 60455-2, test method acc. IEC 60093 | |

| Specific volume resistance | Ω*cm | at 180 °C | 10^9 - 10^11 | IEC 60455-2, test method acc. IEC 60093 |

| Specific volume resistance after 7 d water immersion | Ω*cm | 10^14 - 10^16 | IEC 60455-2, test method acc. IEC 60093 | |

| Creep resistance | typ. value | CTI 275M - 0.4 | IEC 60455-2, test method acc. IEC 60112 | |

| Dielectric constant at 23 °C between 50 Hz and 1 MHz | 4.0 ± 0.5 | IEC 60455-2, test method acc. IEC 60250 | ||

| Loss factor cross section 0.2=200x10^-3 | °C | 110-150 | IEC 60455-2, test method acc. IEC 60250, between 50 Hz and 1 MHz |

| Property | Unit of measure | Values | Test method |

|---|---|---|---|

| Impact on enamelled wires | Compatible with common enamelled wires | acc. IEC 60851-4 | |

| Viscosity | mPas | 700-1300 | at 25 °C acc. DIN 53019 |

| Reaction process gel time | min | 9.5-15.0 | 10 °C, company standard Energy Solutions-001 |

| Reaction process reaction time | min | 10.0-16.0 | 10 °C, company standard Energy Solutions-001 |