Chemistry can also be different

Environmental protection has long ceased to be merely an issue for the future but, despite this, very little is evident in some areas of collective efforts designed to protect the environment. We regard it as a very important task, and we also see in the enforcement of international agreements throughout our sector an opportunity to promote efforts in environmental protection beyond national frontiers.

With more than 200 regulations to date, the European Union is also making its own contribution to environmental issues and consistent action. Each of our customers is very familiar with REACH (Registration, Evaluation, Authorisation and Restriction of Chemicals) ROHS (Restriction of Hazardous Substances, health and safety regulations) and VOC (volatile organic compounds guidelines).

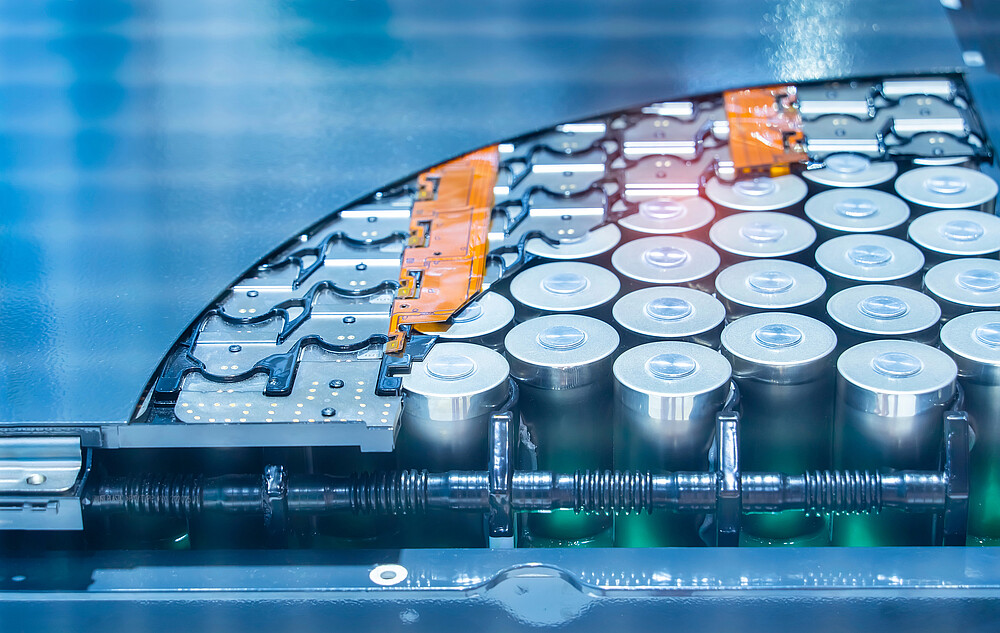

As an example of environmentally friendly products in our range, we are focusing our attention in particular, the field of liquid chemicals which encompass products in the area of impregnating agents at SynFlex. These include varnishes, resins and casting compounds of the latest generation which conform to the latest requirements for environmental protection.

Let us first take a brief look at the real situation on the impregnating agent market. This still primarily involves impregnating resins based on styrene, vinyl toluene and acrylates. Earlier varnishes often contain conventional, volatile solvents (VOC), and also some impregnating resins and multi-component casting compounds are in part rather critically assessed in terms of their handling.

However, a lot has changed in development – for the better for our environment. The range of advanced product solutions that are environmentally friendly and, simultaneously, comply with state-of-the-art technological and safety standards has grown rapidly in recent years. Thanks to the restrictions of EU directives and a strong growth in environmental awareness among downstream producers and consumers, producers are increasingly turning to environmentally friendly raw materials and primary materials.

Even manufacturers of liquid chemicals have reacted and developed “green product ranges”. New environmentally friendly varnishes and resins have led to the promotion of ecological, economic and, in particular, technical aspects, thus uniting environmental compatibility with low costs for processes and maintenance and the highest technical standards.

Some of the best examples of the new green product generation in the SynFlex product range include VOC-free polyester-based impregnating resins with low-viscosity acrylates for reducing viscosity that develop very little odour during the curing process. Where varnishes are required for impregnating for technical reasons, water-based varnishes without or with only very minimal VOC components are available. In the area of casting resins, isolated products are setting milestones in terms of processing and environmental friendliness. There is still a lot of catching up to do in the case of the finishing varnishes. However, high-quality processing technologies can compensate for deficits in occupational safety and environmental protection in this case.

Our aim is to promote the unfortunately still expandable demand for these advanced and considerably more environmentally friendly products and convince both the industrial trade and downstream producers of the benefits of “green products”.

SynFlex would therefore like to support you with expertise and technical service in the further development of this field of work. Our experts can analyse your processes on site and develop ideas with you to take joint responsibility and play our part in protecting the environment.