Laser system for stamped parts and blanks

![[Translate to Englisch:] Laseranlage Schramberg](/fileadmin/_processed_/a/d/csm_shutterstock_251385547_ret2_0895dbe5a5.png)

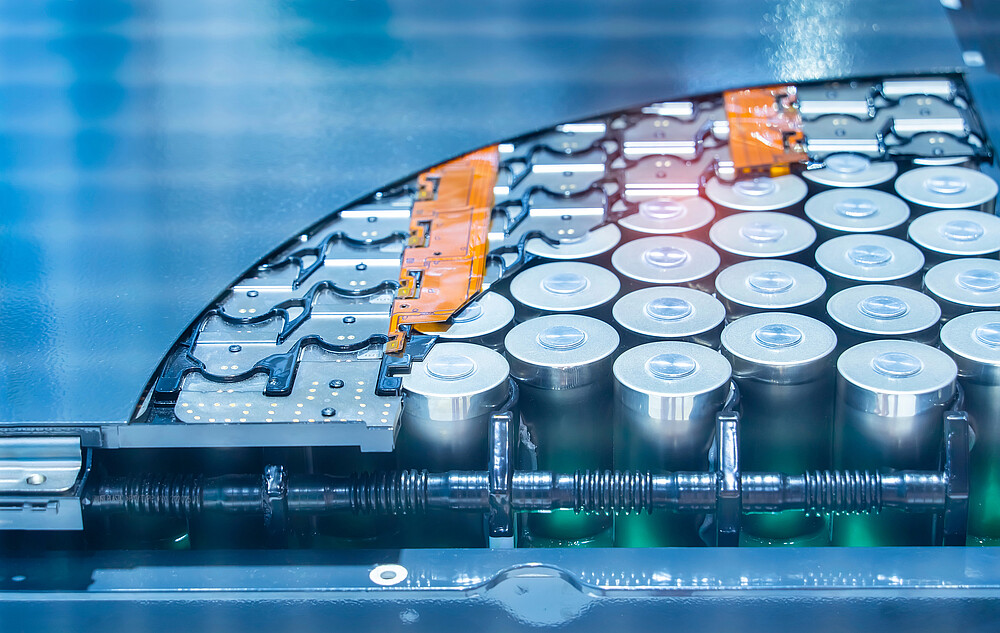

The laser system at the Schramberg site is a system from a well-known manufacturer that specializes in the realization of a wide variety of laser-based systems. Our all-in-one system is specifically designed for processing roll materials. On this basis, the machine is accordingly used as a laser for cutting and engraving our stampings and blanks.

The production center is equipped with a technically sophisticated and complex laser that has cutting, marking and micro-perforating functions as well as a separate laminating and matrix stripping station.

Among others, paper, PET film, polypropylene film and Teonex® are some exemplary materials that can be processed with this machine. The current focus is particularly on insulating materials and nonwovens. The machine is set up for material thicknesses from 0.05 to 1 mm. Processing of thicker materials requires individual testing.

It is possible to process web widths between 100 and 350 mm. Our special production process allows processing of almost unlimited lengths.

This is only a limitation of the part width - longer parts are always possible on request.

Your benefits:

- Generation of pre-production samples without tools to ensure that the planned part can be used in the desired form

- Production of small series

- Machining of complex part shapes that were previously impractical with common punching tools (for example: multiple holes)

- Use of materials that previously could not be processed by means of usual punching techniques.

Our laser is already producing parts for e-mobility, 5G, medical technology and other key technologies of the future - without losing sight of our current projects in the field of electric motors, transformers and generators. Because there, too, we can now realize projects that were impractical before.

Challenge us - we are there for you.