News

Always top-informed! Read all about the latest developments in the SynFlex Group and find the dates for events to meet us personally.

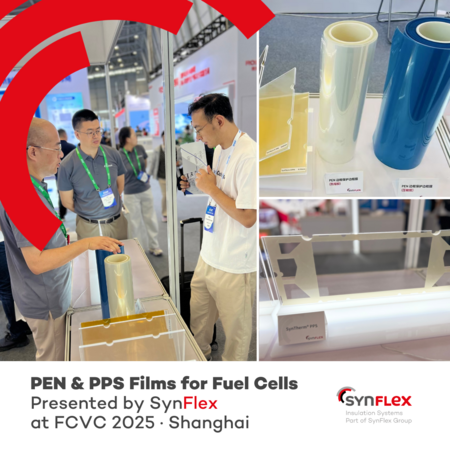

Fuel Cell Vehicle Congress & Exhibition Shanghai

SynFlex Shanghai successfully attended the Fuel Cell Vehicle Congress & Exhibition

Coiltech Pordenone 2025 | Save the Date

Coiltech Pordenone September 17 / 18, 2025!

Coiltech Augsburg - we will be there!

In 2025, we will once again be present at Coiltech in Augsburg on March 26 and 27.

Learn more

SynFlex China receives ISO 14001:2015 certification

SynFlex Group is proud to announce that its production facility in China, has successfully passed the DQS audit and been awarded the ISO 14001:2015 certification.

CWIEME Shanghai 2024

The 11th CWIEME took place in Shanghai from 26 to 28 June 2024 and SynFlex China was there for the 10th time! 268 exhibitors presented themselves to approx. 10,000 visitors on 26,000 m².

Numerous visitors were able to inform themselves about our products. The focus was on laminates, die-cut parts and adhesive tapes and our own SynLab® laboratory with UL certification according to UL 1446 for your electrical insulation systems.

Please see all the impressions we gathered in our video.

Coiltech 2024: SynFlex Group in the spotlight as a leading industry partner

More than 250 valuable discussions with customers, partners and interested parties - these are the successful results of this year's Coiltech in Augsburg (20-21 March 2024).

Learn more

SynFlex Group presents unique alternatives at the Coiltech in Augsburg

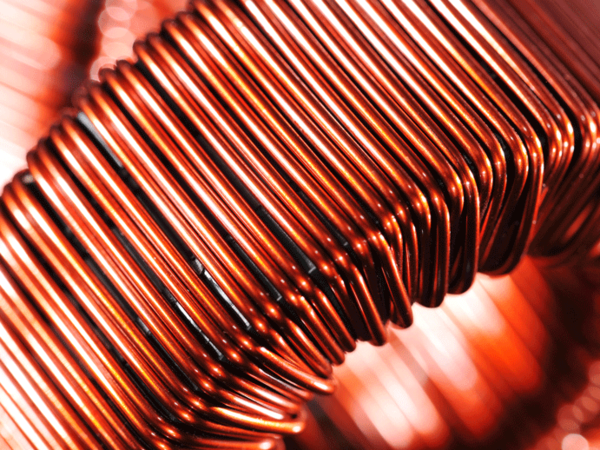

Trade fair highlight from SHWire: SHXLife – the high-performance enamelled copper wire for applications exceeding 800V

Learn more

Coiltech Augsburg - we will be there!

Also in 2025 we will exhibit at Coiltech in Augsburg on March 26 and 27.

Learn more

EVERTIQ Expo Warsaw 2023

On 26.10.2023, the largest event of the electronic industry in Poland – EVERTIQ Expo 2023 took place in Warsaw again.

Organized at the National Stadium in a smart table-top formula, the meeting of industry manufacturers and suppliers (this year over 160 companies) is becoming more extensive every year and provides an excellent opportunity to exchange ideas, establish contacts and create business relationships.

Also this year SynFlex Elektro Polska Sp. z o.o., the Polish company of the SynFlex Group, was represented here. The focus of the presentation was on our products and materials such as copper foils, insulation materials, stamped and moulded parts, potting compounds and adhesive tapes, i.e. all items of our wide range that are used in electronics and contract assembly.

We would like to thank all our customers and visitors for interesting meetings conversations

Your SynFlex Poland Team

Together into the future with sustainability

Join us on the path to a sustainable future and get to know our values and goals. It has been our practice as a family business to harmonize ecological, social and societal aspects - for 164 years.

For us, economic decisions always reflect sustainable and responsible action and are an integral part of our strategy.

Learn more about our sustainability strategy

You want to know more about our activities and measures? Ask for our sustainability report!

esg@synflex-group.com

Monitoring audit 2023 according to IATF 16949:2016 and ISO 9001:2015 successfully passed

SynFlex has successfully passed the certification audits in 2023 at the Blomberg and Schramberg sites, according to the standards IATF 16949:2016 and ISO 9001:20215, as well as at the Innermanzing site in Austria according to ISO 9001:2015.

The standard for QM systems in the automotive industry IATF 16949:2016 defines the industry-specific requirements for series and spare parts production based on DIN EN ISO 9001:2015.

In the course of the annual certification, SynFlex has been audited by the certification company DQS and has successfully passed the certifications at the sites. For this purpose, the processes of the QM system are continuously scrutinized, monitored, evaluated and optimized by the employees. The continuous improvement of system and process quality optimizes customer satisfaction. Thus, we can meet the increasing demands on product quality, productivity and competitiveness and also increase the efficiency for our customers.

"With our certification, we want to show reliability and a high standard of meeting our customers' needs. The certification is a signal of confidence for our business partners", explains Heinz von der Heide, Head of Quality Management at SynFlex.

The successful certification is an achievement of all SynFlex employees.

The blood donation service celebrates its premiere at the SynFlex Group in Blomberg

Together with her team of three, Ms. Ledig (DRK-Blutspendedienst West) regularly prepares the large blood donation vehicle. Today, 50 blood donations are planned, to be given by employees working in shifts.

"As a family business, we are committed to the region and to our fellow man. It's great that so many of our employees have accepted the invitation to donate blood," says Dr. Henning Martens, Director Human Resources & Legal Affairs at SynFlex Elektro GmbH.

Employees from our sister company SHWire (Schwering & Hasse Elektrodraht GmbH) also came to donate. For them, as for the other colleagues who come to donate at a specific time, the first step is a preliminary consultation with the doctor. The doctor checks whether they are suitable donors and then directs them to the mobile unit. Five people can donate at the same time. About half a litre of blood is taken from each person. They then go to the rear VIP area to acclimatise - and then the company provides free refreshments to replenish their fluids.

Ms. Ledig recommends that donors drink plenty of fluids and eat well before giving blood. "Two cups of coffee are not enough, otherwise the blood is much thicker and it is harder to take," says Ms. Ledig. The blood donation service travels almost every day, at least three times a week.

All the blood donors from the SynFlex Group came through the day well, and Ms. Ledig is also satisfied with the result: "We will gladly come again."

Coiltech Pordenone 2023

Also this year SynFlex Italia participated in Coiltech Pordenone from 20 to 21 September 2023.

The fair, which exists since 2010 and is attended by manufacturers of electric motors, generators, transformers and large transformers has become the central meeting point of the Southern European electrical industry.

A large number of visitors came to our stand to find out about our latest developments. In particular, we presented our in-house produced SynTherm® laminates as well as our laboratory services and services according to UL1446. In addition, the wide product range of our stamped and formed parts and adhesive tapes.

We would like to thank all visitors.

Husum Wind 2023

For the first time we presented ourselves as exhibitor at the HUSUM WIND, the most important trade fair for renewable energies in the German speaking area.

As a reliable partner in the field of wind energy, we were present with a special focus on our KIT sets, the Seleeve SynSleeve - H/GS Ultimate Flex as well as our SynWire WW - Special wires.

Please continue to take the opportunity to get to know us: we look forward to working together on a sustainable future!

Summer fair 2023

On 1 September, we held a summer fair for all employees on our headquater in Blomberg.

Despite the rather autumnal weather outlook, the funfair was accompanied by dry weather and pleasant temperatures - a real stroke of luck!

With a variety of tasty treats, exciting games like throwing cans and darts, exciting horse races and of course the indispensable bull riding, the funfair was a real highlight. The grounds were full of employees who were in the best of moods and enjoyed the festival to the fullest.

Our Managing Director, Mr Karsch, opened the bull-riding very skilfully. After the spell was broken, there was a lot of competition among the colleagues.

The party went on until the early hours of the morning - undoubtedly a great success!

Key Account Manager Ukraine (m/f/x)

Customer service is your passion and you also love to work independently as a team player?

We hope for peace in Ukraine soon and would like to offer refugees a chance.

We are therefore looking for a Key Account Manager (m/f/d) with a focus on Ukraine to support our national and international customers. The initial place of work is Germany, with the prospect of a move to Ukraine.

Successful Dragon Boat Regatta 2023

Successful Dragon Boat Regatta 2023 Last Saturday our team "Wire Warriors" took part in the Dragon Boat Regatta 2023 on the SchiederSee.

At 8 o'clock in the morning, the team sat together in the boat for the first time. After a short training session, the first race for the "Wire Warriors" started at 11 am. Our team consisting of 25 SynFlex & SHWire, Schwering & Hasse Elektrodraht employees could not make it to the final in the late afternoon but reached the 4th place in the premium class.

Our team passed the time between the races under the SynFlex Group Pavilion where some tasty treats and cool drinks filled the buffet. After the award ceremony at 6 pm, the "Wire Warriors" started their journey home, exhausted but satisfied.

We are looking forward to next year!

CWIEME Shanghai 2023

After three years, SynFlex China exhibited at the CWIEME Shanghai as one of the important exhibitors. This year 10.091 Visitors meet 255 Exhibitors at the fair ground in Shanghai.

Numerous visitors were able to inform themselves about our products. The focus was on laminates and sleevings. In addition to the friction coefficient measuring device and our own laboratory SynLab® with UL certification according to UL 1446 for your electrical insulation systems.

As a tradition of expressing our gratitude and better connecting with our VIP guests, we hold customer event during the expo every one or two years at most iconic and scenic spots in the city. This year, we treated our VIP guests at a Premium Western Restaurant located along the very famous Bund area in Shanghai with a stunning view of both sides of the Huangpu River.

Sumptuous banquet with delicious food, wine-tasting and cigar hand-making has become a memory of a wonderful night for everyone present.

Cooperation with Thermik Group

We hereby inform you with great pleasure that starting on July 1, 23 our company SynFlex S.A.R.L. and the Thermik Group are working together on the French market in order to be able to offer you the entire Thermik product portfolio!

Customer event Berlin 2023

Despite the decision not to exhibit at the CWIEME in Berlin, we wanted to show our presence and invited our customers present in Berlin to an evening event on 23 May.

Celebration Year 2023 - 900 Years of Lippe

We at SynFlex and SHWire, Schwering & Hasse Elektrodraht would like to extend our warmest congratulations on the 900th anniversary of Lippe and the 50th anniversary of the district of Lippe.

10th Blomberg Training Fair - Training fair in top form!

For the 10th time, we made our logistics and the outdoor area available for the 10th Blomberg training fair, organised by Netzwerk Wirtschaft-Schule.

It was hard to top what the exhibitors put together for the 10th Blomberg Training Fair. There have never been so many exciting trade fair highlights before.

Coiltech Augsburg - a success story

After last year’s launch of the Coiltech in Germany, we exhibited again at the Coiltech on 29 and 30 March 2023, this time in Augsburg.

SynFlex Group planting trees in the Lügde forest

On 2 December 2022, dedicated employees planted 780 oak trees under the supervision of the local forestry employee.

Background to the campaign is the reforestation of local forests in and around Lügde.

EVERTIQ Expo Warsaw 2022

On 27.10.2022, the largest event of the electronic industry in Poland – EVERTIQ Expo 2022 took place in Warsaw.

Organized at the National Stadium in a smart table-top formula, the meeting of industry manufacturers and suppliers is becoming more extensive every year and provides an excellent opportunity to exchange ideas, establish contacts and create business relationships.

Also this year SynFlex Elektro Polska Sp. z o.o., the Polish company of the SynFlex Group, was represented here. The focus of the presentation was on our products and materials such as copper foils, insulation materials, stamped and moulded parts, potting compounds and adhesive tapes, i.e. all items of our wide range that are used in electronics and contract assembly.

We would like to thank all our customers and visitors for interesting meetings conversations

Your SynFlex Poland Team

Coiltech Pordenone 2022

Also this year, SynFlex Italia was represented at the Coiltech Pordenone from 28 to 29 September 2022.

E-22 Electronics Fair in Odense

Congress Center

SynFlex Denmark exhibited at the E-22 Electronics Fair in Odense Congress Center from 30 August to 1 September 2022.

We presented in terms of customized solutions for the electronics industry.

✅ Two-component polyurethane encapsulating systems from leading manufacturers

✅ Foils for industrial printing, MMI panels, fuel cells, packaging etc.

✅ Processed materials for electrical, thermal and mechanical insulation.

✅ Electrical adhesive tapes of strong brands.

![[Translate to Englisch:] E-22 Electronics Fair Odense](/fileadmin/_processed_/3/f/csm_IMG_4563_a9e109779b.jpg)

Successful Dragon Boat Regatta 2022

Last Saturday our team "Wire Warriors" took part in the Dragon Boat Regatta 2022 on the SchiederSee.

At 8 o'clock in the morning, the team sat together in the boat for the first time. After a short training session, the first race for the "Wire Warriors" started at 11 am. Our team consisting of 25 SynFlex & SHWire, Schwering & Hasse Elektrodraht employees could not make it to the final in the late afternoon and finished 11th out of 22.

Our team passed the time between the races under the SynFlex Group Pavilion where some tasty treats and cool drinks filled the buffet. After the award ceremony at 6 pm, the "Wire Warriors" started their journey home, exhausted but satisfied.

We are looking forward to next year!

Monitoring audit 2022 according to IATF 16949 of automotive industry successfully passed

The standard for QM systems in the automotive industry IATF 16949:2016 defines the industry-specific requirements for series and spare part production based on DIN EN ISO 9001:2015.

In the course of the annual certification SynFlex has successfully passed the monitoring audit performed by the certification company DQS. Our employees continuously question, monitor, evaluate and optimize the processes of our QM system and the satisfaction of our customers is optimized through continuous improvement of system and process quality. Thus, we can meet the increasing demands on product quality, productivity and competitiveness and also increase the performance power for our customers.

“With our certification, we want to show reliability and high standard in meeting the needs of our customers. This certification is a signal of trust for our business partners”, explains Heinz von der Heide, Head of Quality Management at SynFlex.

The certification is a success for all SynFlex employees.

Coiltech Ulm 2022

On 6 and 7 April, the SynFlex Group presented itself at the Coiltech that took place for the first time in Ulm.

![[Translate to Englisch:] Coiltech Ulm](/fileadmin/_processed_/4/0/csm_Foto_Nachbericht_1dac660cb8.png)

Production possibilities

Get to know our competence centre for adhesive tapes as well as die-cut and moulded parts at the Schramberg site.

We have prepared some interesting videos for you...

hi Tech & Industry Scandinavia

SynFlex Scandinavia was represented at the hi Tech & Industry in Herning from 5 to 7 October attracted a total of 718 exhibitors in 11 halls.

Recertification audit according to ISO 9001:2015 and IATF 16949 successfully passed

Based on the requirements of DIN EN ISO 9001:2015, the standard for QM systems in the automotive industry IATF 16949:2016 defines the industry-specific requirements for quality management systems of suppliers.

This year, SynFlex starts a new three-year cycle by successfully passing the recertification audit. With the audit the certification company DQS verified that our QM system meets the requirements of the standard and that our employees continuously question, monitor, evaluate and optimize the processes of our QM system.

The satisfaction of our customers is optimized through continuous improvement of system and process quality. Thus, we can meet the increasing demands on product quality, productivity and competitiveness and also increase the performance power for our customers.

A success for all SynFlex employees.

Coiltech Pordenone 2021

Also this year, SynFlex Italia was physically represented at the Coiltech Pordenone from 22 to 23 September 2021.

![[Translate to Englisch:] Coiltech Pordenone](/fileadmin/_processed_/6/d/csm_20210923_090119_ret_e253a45c93.jpg)

Teonex® - PEN film with excellent properties

This polyethylene naphthalate (PEN) film is perfect for high-end applications due to its many superior properties. Teonex® films are ideal for use in automotive applications (traction motors, hermetic motors) as well as industrial applications.

Learn more

![[Translate to Englisch:] Teonex®](/fileadmin/_processed_/9/5/csm_SynTherm_Teonex_Q51_4cfc3874c4.png)

Cooperation with Thermik Group

We hereby inform you with great pleasure that our company SynFlex Italia Srl and the Thermik Group are working together on the Italian market in order to be able to offer you the entire Thermik product portfolio!

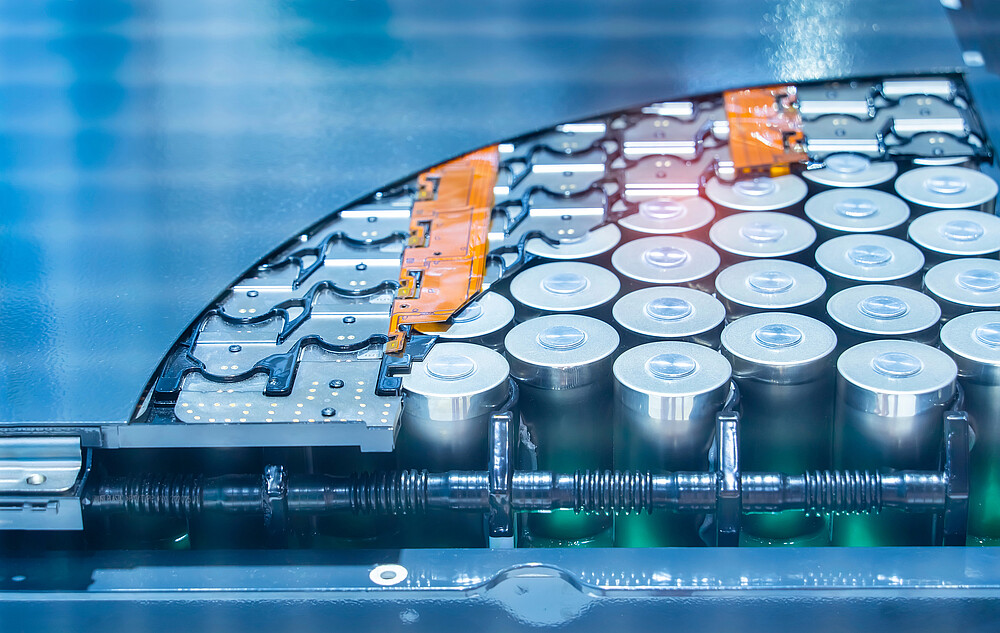

Products for batteries

While the development of rechargeable batteries for the automotive sector and stationary applications is breaking new ground or even going down new paths virtually every day, we can already contribute a stable component that has been developed for decades: insulation - both electrical and thermal.

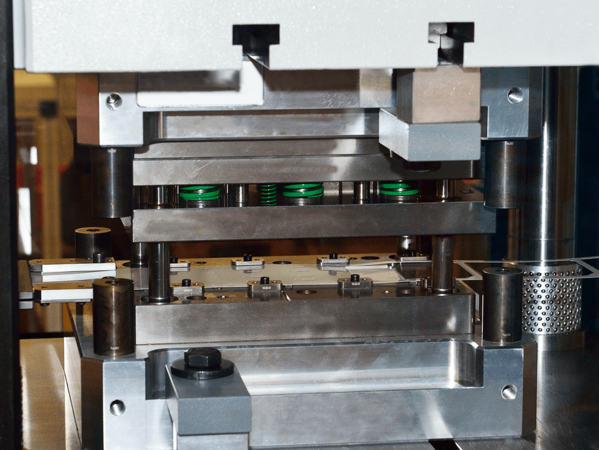

Male-female punching unit for

the Schramberg location

By investing in the new male-female tool punching machine at our production site in Schramberg we are taking the logical next step in our production capabilities.

Monitoring audit 2020 according to IATF 16949

of the automotive industry successfully passed

The standard for QM systems in the automotive industry IATF 16949:2016 defines the sector-specific requirements for series and spare parts production based on DIN EN ISO 9001:2015.

In the course of the annual certification SynFlex has successfully passed the surveillance audit by the certification company DQS. For this purpose, processes of the QM system are continuously questioned, monitored, evaluated and optimized by the employees. Customer satisfaction is optimized by the continuous improvement of system and process quality. This enables us to meet the increasing demands on product quality, productivity and competitiveness and also to increase the performance for our customers.

A success for all SynFlex employees.

Availability of goods in uncertain times

The Corona pandemic has shown how fragile supply chains can be, especially when products are sourced globally. The risk of production stoppages increases and with it the risk of delivery of finished products to the respective customer.

Highest quality at all levels

Quality in the inquiry phase

For us, quality is the fulfilment of your requirements. In order to jointly develop tailor-made solutions for your needs, we evaluate the feasibility of your request with a focus on risk minimization in interdisciplinary teams.

Finals Makeathon #horizonteOWL

The SynFlex Group participated in the newly created it´s OWL Makeathon and made it to the finals!

Makeathon #horizonteOWL

Together with 17 other companies we have submitted a challenge for the Makeathon #horizonteOWL.

What is the Makeathon #horizonteOWL?

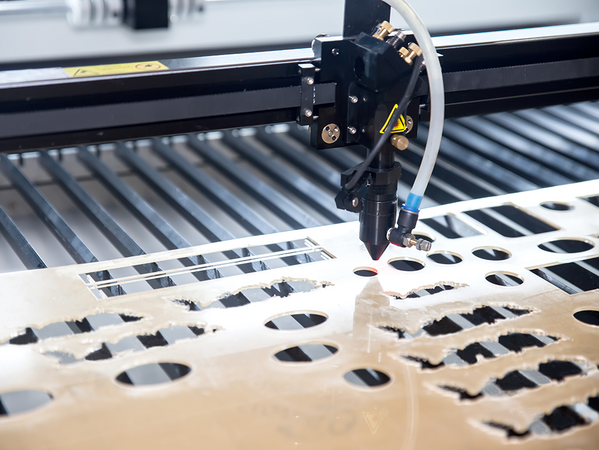

Laser system for stamped parts and blanks

The laser system at the Schramberg site is a system from a well-known manufacturer that specializes in the realization of a wide variety of laser-based systems. Our all-in-one system is specifically designed for processing roll materials. On this basis, the machine is accordingly used as a laser for cutting and engraving our stampings and blanks.

„Room for unconventional thinking“

Schwering & Hasse Elektrodraht GmbH in Lügde develops and produces enamelled copper and aluminium wires at the largest and most modern independent production site in Europe. In order to identify additional optimization potential in production, the company has invited to a Transfer Challenge and has named challenges for which they expect innovative ideas from outside.

Lean more

Digital magnet wire slide rule

With the digital magnet wire slide rule we have brought the well-known and popular handy tool from the desk to the desktop. Simply enter the desired nominal wire diameter via the input field or use the slider. At a glance you will find useful information on enamelled copper and aluminium wires based on IEC 60317-0-1.

We were there

With 44,000 visitors and 1,500 exhibitors from 44 countries, Productronica is increasingly regarded as the world's leading trade fair for electronics production.

Takeover "Adhesive Tapes" of Von Roll Deutschland GmbH

As of 31 December 2019 / 01 January 2020 SynFlex Elektro GmbH will take over the business division "Adhesive Tapes" of the Von Roll Deutschland GmbH, Augsburg / Germany.

hi Tech & Industry Scandinavia

SynFlex Scandinavia was represented at the hi Tech & Industry in Herning from 1 to 3 October. This fair is the largest technology and industry fair in Scandinavia and attracted a total of 718 exhibitors in 11 halls.

Individual insulating materials for your project

As a long-standing partner for insulating materials, we offer you various surface insulating materials, each tailored to your needs.

In addition to our standard products such as resilient pressboards or high-temperature resistant aramid papers, we are known for our individual multi-layer laminates from our own production.

Find out more about our possibilities and develop the right solution for you jointly with us.

Coiltech Pordenone

SynFlex Italia presented products and services of the SynFlex Group at this year's Coiltech in Pordenone, Italy. With over 400 exhibitors and manufacturers of electric motors, generators, transformers and large transformers the fair has established itself as a meeting place for the Southern European electrical industry since 2010.

Safety and assembly convenience

Our large selection of transformer terminal blocks is tailored to the diverse specifications of transformer manufacturers. Additionally to the wide range of cross-sections and connection technologies we have practical accessories like marking systems for you.

Lean more

Pad-cleaning tapes

The Target is clear: the customer wants to have the perfect printing result.

One of the main factors, which is unfortunately often ignored, is the cleanliness of the printing process. It is not enough to apply the ink safely to the end product. The stamp must be perfectly cleaned for the next printing process. Pad-cleaning tapes of SynFlex have exactly these properties by reliably removing residual ink and dirt.

The SynFlex Group introduces itself

If you want to shape the future, you need strong partners. SynFlex has found these partners with the companies SHWire and IsoTek, united in the SynFlex Group.

Together, we bundle our competencies in the SynFlex Group, make use of synergies and offer customers added value that is unmatched in our industry.

IEC 1906 Award – Expert knowledge honored

SHWire and SynFlex are very active in national and international standards bodies. These worldwide valid so-called IEC standards describe the state of the art regarding important tests and product properties, e.g. for winding wires in the 60317 and 60851 series of standards. Our customers can refer to these comprehensively and reliably and also agree on specific tests or properties.

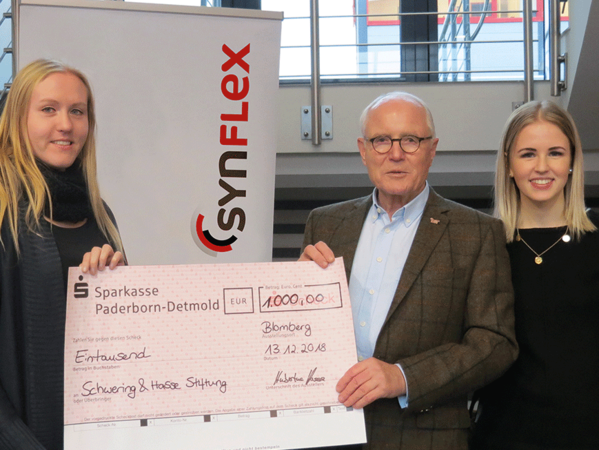

Shopping for the good cause

The year is drawing to a close, the time of contemplation has come and we are presenting gifts to loved ones. But also there are many people around us who need our support. The Schwering & Hasse Foundation is committed to these people in the city of Lügde and the region. Especially the children are in the foreground.

Certification of real-life Practice

Until recently, the standard for QM systems in the automotive industry was ISO/TS 16949. It defines the additional industry-specific requirements for the production of series parts and spare parts in the automotive industry. This has been replaced by IATF 16949. SynFlex successfully completed the transition audit for IATF 16949:2016 in September 2018 and is therefore one of the first among the very few in the industry.

Chemistry can also be different

Environmental protection has long ceased to be merely an issue for the future but, despite this, very little is evident in some areas of collective efforts designed to protect the environment. We regard it as a very important task, and we also see in the enforcement of international agreements throughout our sector an opportunity to promote efforts in environmental protection beyond national frontiers.

Industry 4.0

Production secures prosperity, employment and, ultimately, the future for all of us. During times in which we see relocation to low-wage countries, the European economy asserts itself through flexibility, quality and stability. This applies in particular to the winding industry.

Growing significance of the EU railway standard

When it comes to the safety of passengers and personnel, use of the final product and individual components in railway technology involves the strictest demands along the entire manufacturing chain. The regulations in DIN EN 45545 must be observed to detect and evaluate any hazard potential at an early stage.

10 years high-bay warehouse

Smooth logistics have for many years been one of the basic demands customers make of a system provider such as SynFlex. Expressions such as just-in-time and 24-hour delivery service have now become an indispensable service which many customers no longer wish to do without.

Two jubilees, two success stories

A company jubilee is a very special event. Together, the enterprise, its employees and customers can look back on the many milestones achieved, tricky challenges and successful moments. Two very special birthdays will be celebrated at SynFlex in 2017: 10 years of SynFlex China and 20 years of SynFlex Italy. Two jubilees, and two success stories that need to be told.

SynFlex A/S’ 25th anniversary

The history of the second international subsidiary of the SynFlex Group began as a result of the acquisition of Eldra GmbH in Austria in 1993. The reason being that Eldra GmbH initially owned 50 % of the shares of company John Hjalholt A/S which had been the Danish distributor at that time.